by Debra Cobb

Heat shields are a critical part of vehicles for space exploration, enabling science payloads to safely pass through the atmosphere of distant worlds. NASA’s deployable heat shield design called ADEPT (Adaptable, Deployable, Entry and Placement Technology) is one such component.

Key to ADEPT’s success is its ability to be compactly packed for launch and storage, deploying like an umbrella when entering a planetary atmosphere. But early iterations of the heat shield were comprised of stitched-together panels, which exhibited stress and discontinuities within the material.

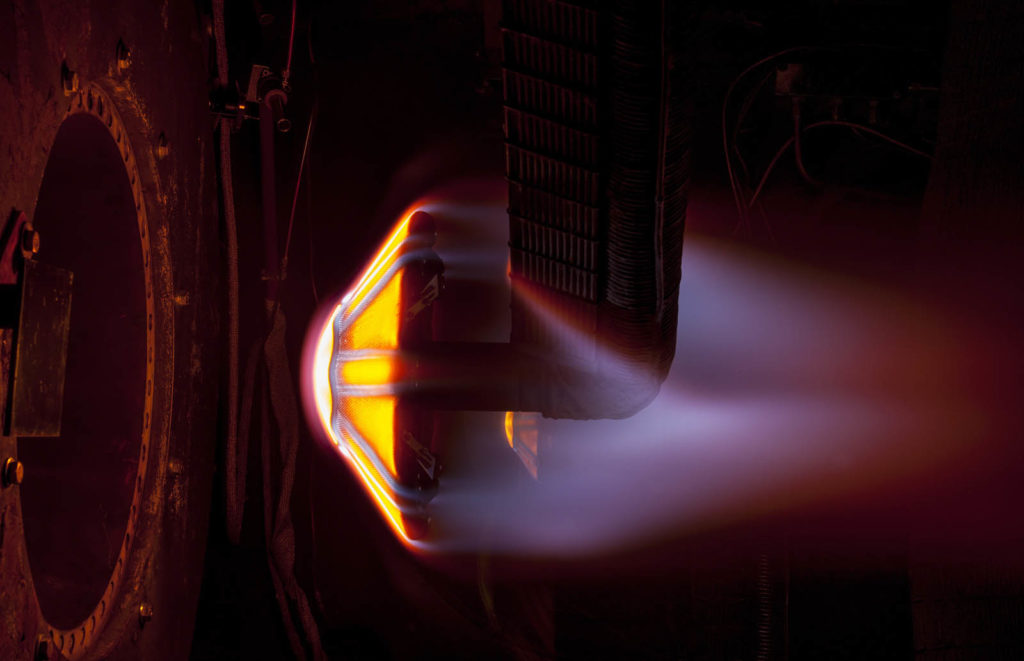

A new 3D woven seamless textile called Spiderweave, developed by Bally Ribbon Mills, Bally, Pa., passed an initial test this summer in the arc jet facilities at NASA’s Ames Research Center in California’s Silicon Valley. The ADEPT team observed how the material held up when exposed to temperatures above 3,000˚F.

Bally senior textile engineer and developer of the “spider weaving” technique, Curt Wilkinson, describes the 3D Spider Woven ADEPT aeroshell as, “a continuous one-piece weave, woven to the ADEPT aeroshell configuration. The preform is woven with standard intermediate modulus carbon fiber. The weave is a 4-layer, plain weave layer-to-layer pattern.”

Bally Ribbon Mills developed the Spiderweave Material as a part of NASA’s Small Business Innovation Research program. Using high strength fibers like Kevlar®, Technora®, and Vectran®, Bally produces lightweight, high performance materials, complex webbings, and structural preforms woven in 3D, T, X, and Pi configurations for many types of aerospace products, including both military and commercial.

Debra Cobb is a freelance writer with textiles expertise. She lives in North Carolina and is a frequent contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG