New materials help to maintain thermal comfort indoors or out.

By Debra Cobb

With COP 26 in the rearview mirror, the remediation of climate change remains uncertain. While the struggle to limit global warming to 1.5˚C above pre-industrial levels will continue, scientists are also looking at ways to mitigate the negative effects of climate change through apparel textiles that provide a level of personal thermal management.

Dissipating radiated heat

The heat of solar radiation, as well as infrared radiation emitted by the body, both make us feel uncomfortably warm. Scientists are working with the nanoporous textile materials polytetrafluoroethylene (PTFE) and polyethylene (PE) in configurations that regulate the radiation of different spectral bands in order to achieve excellent cooling performance on the human body in summer heat.

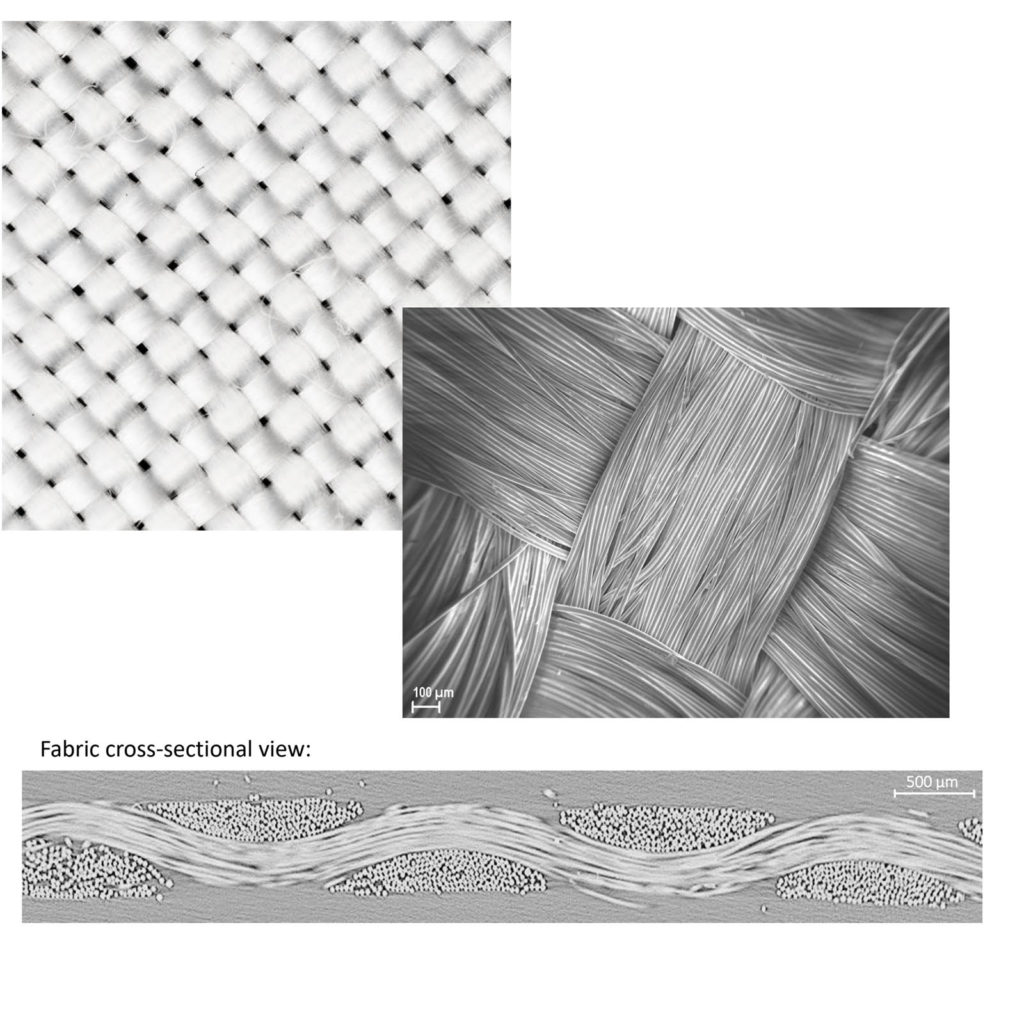

A team led by Professor Guangming Tao from Huazhong University of Science and Technology and Professor Yaoguang Ma from Zhejiang University have developed something called a “metafabric” that reflects sunlight as well as maximizing the heat dissipation caused by mid-infrared radiation. The metafabric consists of titanium dioxide nanoparticle-embedded polylactic acid fibers and a PTFE clothing film. The metafabric not only reflects solar radiation, but also emits infrared radiation for heat dissipation. The body is cooled through heat exchange with the metafabric.

“The metafabric can be used in many occupations and scenarios, such as express service, police and athletes,” says Tao. “Most people engaged in these occupations work in outdoor environments, and have an urgent need for sunlight protection and cooling. Physics can help the clothing industry significantly. This technology can be seamlessly connected with mature modern manufacturing, serving the entire industrial chain from fiber to clothing.”

Passive cooling, with benefits

Scientists from MIT’s Dept. of Mechanical Engineering have found a way to modify fibers of PE, found in plastic wrap and grocery bags, to create fabrics that absorb and evaporate water more quickly than common textiles such as cotton, nylon and polyester.

The nanopores in fabrics made of PE allow heat to escape rather than trapping it against the body. However, PE is normally hydrophobic. By extruding the PE and bundling the fibers, the surface energy becomes weakly hydrophilic, and the spaces between fibers form capillaries through which water molecules can be passively absorbed. The absorption and evaporation creates passive cooling.

In addition, using a standard textile lifecycle assessment tool to measure PE’s physical properties, the researchers found it would require less energy to produce PE textiles, compared to polyester and cotton.

MIT research scientist Svetlana Boriskina reports, “We’ve launched a start-up company from MIT called NERAMCO, which focuses on the PE textiles technology, de-risking and bringing it to the market. We also work with the military and industrial partners (TEK Holding, Under Armor, New Balance and Cosmic Shielding Corp; The U.S. Navy and Army) on applications in sports apparel, tactical textiles and textiles for applications in outer space for radiation shielding and heat management.”

Both sides now

In China, another team is using expanded PTFE as the base for a reversible textile, which when used in reversible apparel could potentially provide both warming and cooling functions, according to its inventors.

Zhejiang University’s Qiang Li and Westlake University’s Min Qiu report that the breathable “Janus” textile features zinc and copper nanoparticles on the warming side of the fabric, which absorb solar energy and reduce the amount of body heat that escapes. The cooling side of the textile has a porous coating of PMMA (polymethyl methacrylate) polymer which reflects sunlight when facing outward, helping to dissipate body heat.

Energy-saving apparel

Pursuing the development of textiles that could provide consumers with personal thermal management technologies, Stanford University’s director of advanced materials laboratory Professor Yi Cui and his team created LifeLabs Design Inc. in 2020. The company recently launched CoolLife, an apparel textile made from nanoporous PE. CoolLife is positioned as the only thermally and infrared-transparent fabric that releases virtually 100 percent of body heat and lowers body temperature by two degrees.

In addition to CoolLife, the company has developed WarmLife, a technology that uses an aluminum nanocoating—less than a paper clip’s worth—to create textiles that return 100 percent of the body’s radiant heat, without affecting breathability. Using 30 percent less material to create a comparable CLO value, WarmLife garments are lighter and more packable than those using traditional insulation materials.

LifeLabs is already trialing its modern, energy-saving apparel on its website, “thanks to a network of proprietary partnerships that have been part of the development process and now the scaling process,” says LifeLabs’ CEO Scott Mellin, who joined the company in April 2021.

Mellin describes LifeLabs as a direct-to-consumer apparel brand. “But we are also selling fabrics to select, competent brand partners to accelerate adoption and scaling of our materials to help consumers reduce their personal carbon footprint,” he says.

Calling this initial drop “just the tip of the iceberg,” Mellin describes a global plan that includes textiles for sleepwear and home goods, workwear, footwear, mobility and others. The company is looking towards the development of coordinating materials and components to promote product circularity.

“We are reimagining the efficacy of textiles to improve the human condition,” says Mellin.

Graphene technology goes commercial

While graphene is recognized as one of the thinnest, lightest and most heat-conductive materials available, it has been considered too costly for commercial apparel. Reebok International Ltd.’s THERMOWARM + GRAPHENE sportswear collection utilizes graphene as a grid print in the garments’ most pivotal heat retention zones to absorb and retain body heat.

Reebok says that the strategically placed technology helps retain between 8 and 15 percent more heat than unprinted zones.

Chandler Frost, senior product manager at Reebok, explains that the technology enables the company to maintain commercial, competitive price points throughout the collection. “Not only has Reebok’s new THERMOWARM + GRAPHENE apparel collection received positive feedback from customers, and extremely strong initial sell-through, but we’re also thrilled that the collection has already received award recognition—thus proving how pivotal the technology will be for the future of sportswear,” says Frost.

“We are still in the early innings of exploring all the ways graphene can be utilized on sportswear, and we can’t wait to see what the future holds,” he adds.

Debra Cobb is a freelance writer with textile expertise. She lives in North Carolina and is a frequent contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG