New collaborations sparked by COVID-19 are set to support growth for the sector.

by Seshadri Ramkumar

The shortage of personnel protective equipment (PPE) has spearheaded creative efforts around the world, with researchers working to produce new PPE products in an effort to meet the needs fueled by the pandemic. 3D printing has also supported the development of textile structures, including face masks and shields. It’s not surprising that 3D technology would be considered, given the growth that’s anticipated in this market.

A survey published in a recent article in Safety Science points out that since the advent of COVID-19, more than 140 groups from 36 countries and over 18,000 individuals have been engaged in the 3D printing of PPE products. The market value of this sector, as reported by various sources, is expected to be between $35–64 billion by the year 2024, with a cumulative annual growth rate (CAGR) of more than 20 percent.

Its origins and growth

3D printing which has become a common technology in engineering and manufacturing, has its origin as “stereolithography,” based on a patent by inventor Charles Hull in the 1980s. This technique came into vogue as a rapid prototyping technology but has evolved as a mass production technique for specialized items.

Early in the evolution, the dental materials sector took notice of this technology to develop implants, and the dental field has continued to be a pioneer in using surgical implants. These were first made using a pressure technique, which may not be flexible, but the products are safe and efficient.

In a collaborative effort with the School of Dental Sciences, University of Leeds, U.K., I worked on developing an artificial human finger using a polymer. While shapes and contours were achieved using the pressure molding procedure, flexibility has been an issue. This drawback has been fairly overcome by the layer-by-layer assembly methods and 3D printing techniques.

Additive manufacturing (3D printing), involves melting polymeric materials and layering them to develop 3D products. These products find applications in sectors such as automobile, aerospace, textiles and fashion, dental and medicine. Although, 3D printed objects find value-added applications, with increased productivity and affordable costs of machines, it is becoming a common manufacturing technique.

The U.S. military is among those entities using the technology. Recently, the U.S. Air Force announced that it will use a 3D printed protective cover component in the B-2 Spirit Stealth Bomber to prevent the accidental activation of the switch that connects the engines to the hydraulic and power generators. The U.S. Dept. of Defense has for many years been using the 3D printing technology. Researchers at Aberdeen Proving Ground, Md., have developed components for a 40 mm grenade launcher. Navy’s Fleet Readiness Center Southwest, Jacksonville, FL have developed lightweight hydraulic component for V-22 Osprey aircraft.

Art to mask

The textile industry is now effectively utilizing 3D printing to mass-produce value-added products and fashion items. The technology and process make it possible to offer consumers perfect fit and design preferences. The experience gained has supported growth in using 3D printing for textiles in medical applications, as well. Face shields, intubation chambers and ventilator parts have been printed using 3D techniques.

A team of researchers from the component institutions in the Texas Tech University system has formed the “West Texas 3D COVID-19 Relief Consortium” to use available 3D printers to produce PPE. This 3D product development effort has opened up collaborations among fields that normally do not interact, such as the School of Theater and Dance, and athletics.

While polycarbonate is the raw material for face shields, textile components such as elastomeric strips and textile headbands have become necessary for final products. Such 3D collaborative efforts in the near future will lead to interdisciplinary efforts such as “Arts in Medicine,” which is already gaining popularity.

“In the early days of the pandemic, PPE was in short supply, says Robert V. Duncan, President’s Distinguished Chair in Physics at Texas Tech University. “It was useful to be able to 3D print PPE such as face shields and masks. Also, people from around the world could share PPE designs and then print their designs, modified if necessary, on their own 3D printers. This is the big advantage of 3D printing.”

Duncan’s group has effectively used 3D techniques to develop PPE items. They have used thermoplastic polyurethane material to print masks, so that the masks are more flexible than many rigid 3D printed objects. This flexibility and tenacity are important characteristics for 3D printed materials. Another example of 3D printed materials is nasopharyngeal swabs, which are important in the present scenario, as well.

Partnership matters

COVID-19 has strengthened the belief that the acceptance of a technique or a product depends on the end-user community. In the case of 3D objects for medical use, comfort, stretch and functionality matters. The functionality, efficiency and design aspects depend on the type of the material that is used in the development of 3D products. In the 3D manufacturing field, printer manufacturer, precursor (filament) maker and the polymer synthesizers are all important.

This partnership is valuable in the effort to enhance the use and affordability of 3D materials. For example, Chinese filament maker Polymaker has collaborated with German polymer company Covestro to develop different varieties of polycarbonate filaments that have good flexibility, as well as heat and flame resistance.

Engineered textile structures

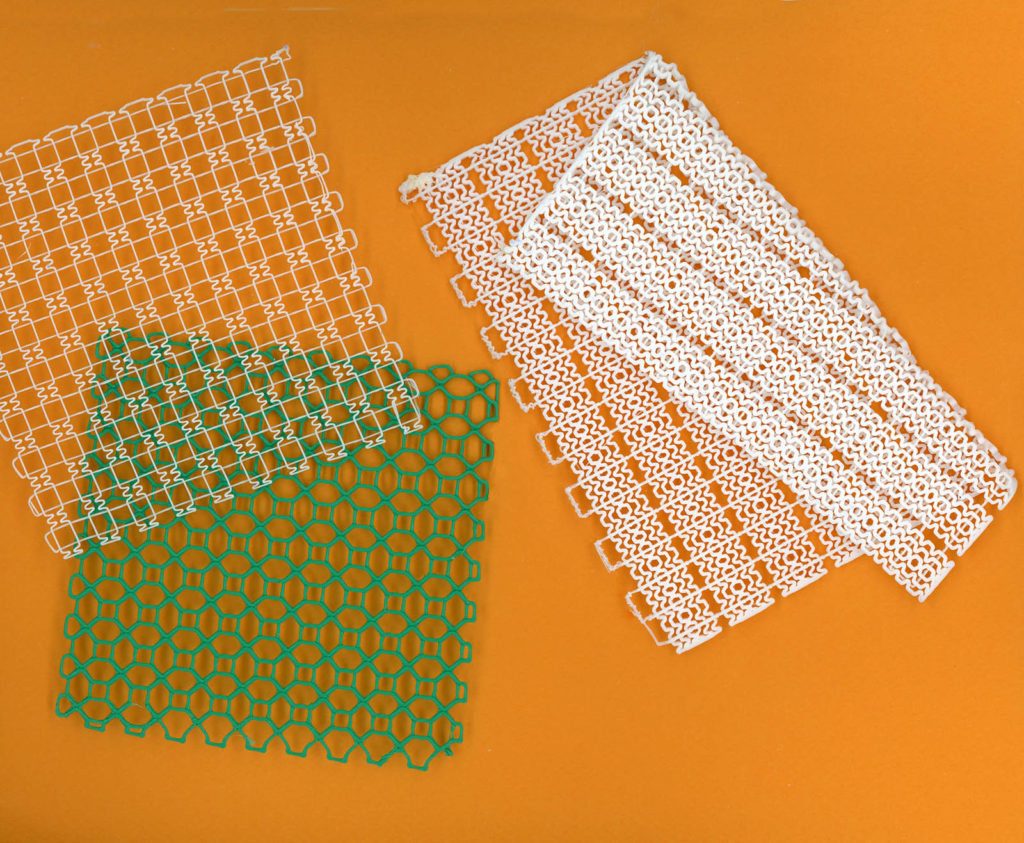

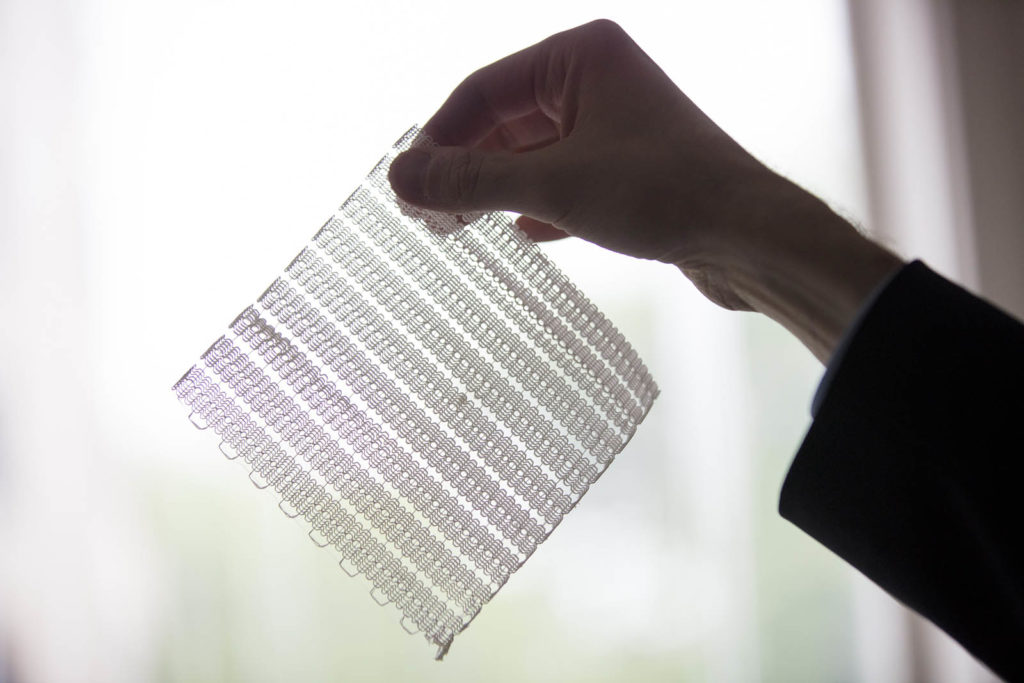

Textile-based structures made using 3D printing have found applications in other medical fields. A group of MIT researchers has used this technology to develop pliable ankle and knee braces. With the help of 3D printing, a biomimetic approach has been followed to mimic the characteristics of collagen in the laboratory.

According to Sebastian Pattinson, a researcher in the group, collagen stretches easily and once tightly pulled, the structures toughen. This property was emulated in polyurethane with the help of additive manufacturing to develop meshes. According to the researchers, meshes increased the ankle’s stiffness while in inversion, and as the ankle moved in other directions, stiffness remained unaffected. The research also revealed that depending on the application and the type of products, the need and property of raw materials would vary.

Ample opportunities

COVID-19 has brought partners from different fields to mass produce textile items that are primarily aimed at providing protection. The type of precursor and method of printing (layer by layer), when optimized and fine-tuned, provide functional characteristics and hence generate new applications.

It has become clear that 3D printing is able to be a mass-production manufacturing technology. While a few precursors, such as polycarbonate and polyurethane, have been widely experimented with, recent developments show that there are opportunities for new precursors as the functionality and property requirements may vary.

The field offers wide scope for chemists, biologists, manufacturing technologists and material engineers to work collaboratively. Clearly, COVID-19 has created a spark in this regard and has helped to pave the road towards steep growth for this sector.

Seshadri Ramkumar, Ph.D., is a professor in the Nonwovens and Advanced Materials Laboratory, Texas Tech University, and a frequent contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG