Editor’s note: This month in our features we’re looking at the question, “What defined the advanced textiles industry in 2022?” I asked the Advanced Textiles Association (ATA) board chair, Amy Bircher, and the ATA 1st vice chair, Roy Chism, to respond to my questions about the industry in 2022 and where we may be going in 2023.

Q: Recovering from the pandemic. Or not. How would you characterize the way in which the industry recovered from the onset of the pandemic, right through to a rethinking, perhaps, of how to do business in a pandemic-era world? What strikes you about where we are right now at the end of 2022?

Bircher: Post-Covid business looks a whole lot different than it does pre-Covid and is most likely here to stay. Flexibility options for hiring and pay rates are much higher than they used to be. Along with supply chain issues, inflation and labor shortages really caused “heartburn” for many organizations, but also [offered] an opportunity to embrace change and get creative on business approaches, presenting ways for all of us to reimagine business, have failures and learn from those mistakes. I’d put the word “resilient” at an all-time high in characterizing businesses.

Chism: ATA membership is broad, diverse, and the recovery I observed reflected exactly those characteristics. In terms of doing business post-pandemic, the “new normal” may be defined as much or more by the influences of demographic shifts in workforce availability and consumer demand, as well as new product development. In terms of where we are [and should be going], it’s got to be re-shoring to the Americas.

Q: What about the movement towards a more sustainable industry?

Bircher: Sustainability and the efforts around it will continue to get more attention and drive businesses to make investments in those practices and products to stay relevant and important in the industry. PFAS is a perfect example of an issue that has gained serious momentum and is banned in many areas throughout the USA. But it really depends on how much someone is invested in it in their business. We track and recycle anything we can in our Lenoir facility. We have a whole sustainable fabric line we offer.

Chism: [Sustainability is not the same for everyone.] The topic of sustainability is so broad and nebulous that it’s hard to get a handle on a brief response without a specific context.

Q: Supply chain issues. What has the last year or two been like for you and your colleagues? What’s changed? What hasn’t? Are we looking at a paradigm shift, ultimately?

Bircher: A lot of the supply chain issues that our industry faced, and several of the businesses that slowed down were ones that took on imported products due to logistic issues. We had a smaller, import supply chain base, and a lot of our products were relatively “chainless.” The industry was rather soft last year, which helped to soften the blow last year for supply chain issues. All of sudden, you didn’t need as much product, and inventories increased because of this.

[With shipping containers] sitting on the water, for a long period of time out in Long Beach, it was hard because many businesses were dependent on important products [waiting to be transported]. Finding different supply chain options out of other countries was actually a really smart exercise to have to go through to mitigate risk. That’s a positive that came out of it for some.

Chism: In a word, “disruptive,” and all that the term can imply. What’s changed? Almost everything. To what hasn’t … hopefully relationships. Certainly, relationships are a core industry strength that was critical to working through the pandemic.

Paradigm shift? I say we are already in it finally and thankfully. But there are huge workarounds, [such as] a huge imbalance in energy availability. For some ATA [European] member companies, where do they get reliable, affordable energy? It gets much more expensive to produce a product with higher energy costs.

Everybody’s sensitive to the long distribution changes. [With changes in where product is made, the distribution locations also change.] Mexico, especially, is going to get bigger; more is going to get produced there. There will be a shift to shorter supply chains and an emphasis on building things and supplying things closer to home–if you can. So, distribution centers need to be closer.

Q: How we manufacture. Equipment, digital and AI technologies, processes, personnel and the human side of the workforce, subcontracting. With so many companies discovering (of necessity) that they could make something else, at least some companies must be rethinking just exactly how they make what they make. There has to be more to this story, and I am wondering, did we just go back to where we were in 2019?

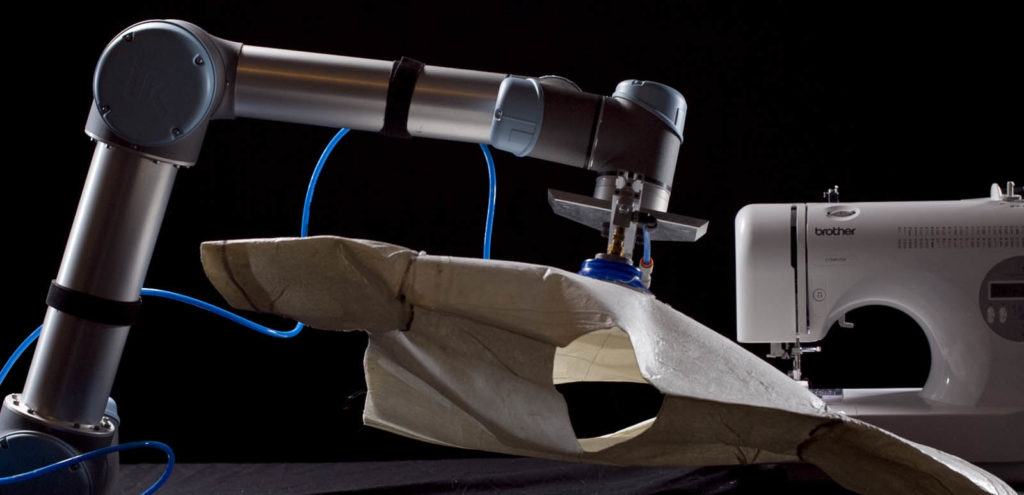

Bircher: I don’t see us going back to 2019 in many cases, but some manufacturing entities haven’t missed a beat with this model, with the exception of having enough people. I know many of us have worked hard to set up new equipment that has an automated feature and requires fewer people in order to be able to handle labor shortages, make product better and faster, and focus on niche products that have seen a reduction in supplier options.

As it relates to textiles, there’s never enough in terms of the skillsets needed for either making the textiles, weaving looms, dyeing and finishing, sewing. These are very special skills.

You don’t have the ability to have flex-time in manufacturing. Younger people want all this flexibility. There’s a whole issue with working with the next generation: what they want to do with their lives. It’s something that’s going to be hard to change quickly.

There’s also the issue of immigration. [It would help if they] make it easier to get skilled workers. It would be a shot in the arm for our industry; immigrants could propel us forward. Setting up an ambassador/apprentice program in our Lenoir factory has been important to us so that they can train someone new before they leave.

Chism: There may be some value here in age-old axioms of resistance to change is the foremost obstacle to be overcome, and necessity is the mother of invention. People can run their businesses as they choose, and they may be happy and comfortable where they are, but with fewer people to produce goods, you need to leverage those people to produce more with more accuracy and repeatability, and machines allow for that. It’s a big resource.

We started automating back in the 80s and it has increased our ability to make product tremendously. We’ve continued to automate and now can produce much more than the core products. Most all of our machinery is computerized. We use single-work cells that do what they do very fast, and we have software that ties all of our machines together.

Q: So, let’s go back to the initial question: what defined the industry in 2022?

Bircher: One word: resiliency!

Chism: Change is constant. Opportunities change all the time. The speed with which you can keep up with that is important. On any given day, it’s change. Obviously, we had a large sector of our industry that mobilized to make PPE shift very quickly with a distribution channel that they had no connection to before.

We don’t know what opportunity might present itself next. Be as prepared as you can be. ATA is a broad and diverse association offering plenty of support and cooperation.

Amy Bircher is CEO and Founder of MMI Textiles headquartered in Ohio. Roy Chism is owner of The Chism Co. based in Texas.

Janet Preus is senior editor of Textile Technology Source. She can be reached at janet.preus@textiles.org.

TEXTILES.ORG

TEXTILES.ORG