There is no shortage of innovation in medical textiles, but it remains a persistent challenge to get those great ideas to market. In terms of patents filed, medical technology is showing relatively slow growth among the technology fields—just 6.5 percent during the period 2008–2018, according to the World Intellectual Property Organization (WIPO).

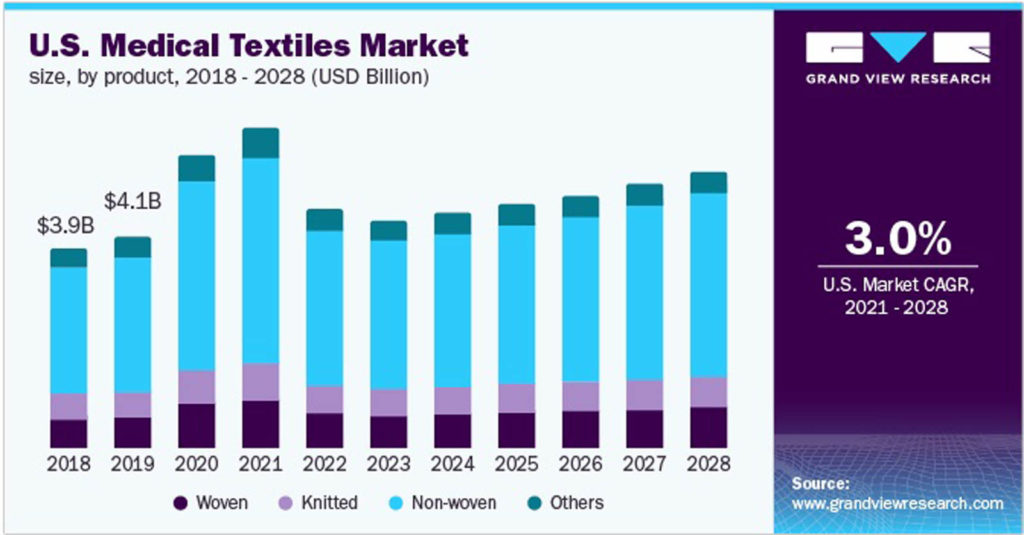

Around 40 percent of filed patents, including those relating to medical textiles, advanced to the point of market launch and mass production according to researchers at the University of Melbourne, Australia. The global medical textiles market size was valued at $24.70 billion in 2020 according to Grand View Research, and it is expected to expand at a compound annual growth rate (CAGR) of 4.5 percent from 2021 to 2028.

The motivation to get from idea to full commercialization is there. In the examples discussed below, two very different routes to market show what is possible.

Start-up to Target

Jordan Schindler is the CEO and driving force behind Nufabryx®, founded a decade ago and located in the heart of the U.S. textiles industry in Charlotte, North Carolina. In 2021 the company was recognized as the fastest growing business in the region by the Charlotte Business Journal. The company’s patented technology stores and releases active ingredients delivering therapeutic amounts to the skin. At the time the company was launched both it and the market sector of ‘healthwear,’ as Schindler refers to it, were new. Both have grown together, and it would seem at a pace that has not overreached.

Speaking at industry events, such as IFAI’s Expo, Schindler has shown his knowledge without overstating technology claims. Additionally, Nufabryx’s decision to retain their base in North Carolina, rather than seek lower costs overseas, has also supported the company’s steady growth by building strong relationships with established mills nearby. In this way they have made been able to make product available in stores such as Target and Walmart nationwide.

The company plans to expand product lines in pain relief such as topical analgesic-infused back wrap and neck sleeves, shea butter moisturizing-infused yoga pants and leggings, and a melatonin-infused line of sleepwear and bedding.

Persistence and patience

Each year academia generates a wealth of research in medical and health textiles; however, far fewer go on to reach the market. Commercialization departments and incubation zones are well established in many universities, but these have a limited lifetime for the graduate who must eventually move on.

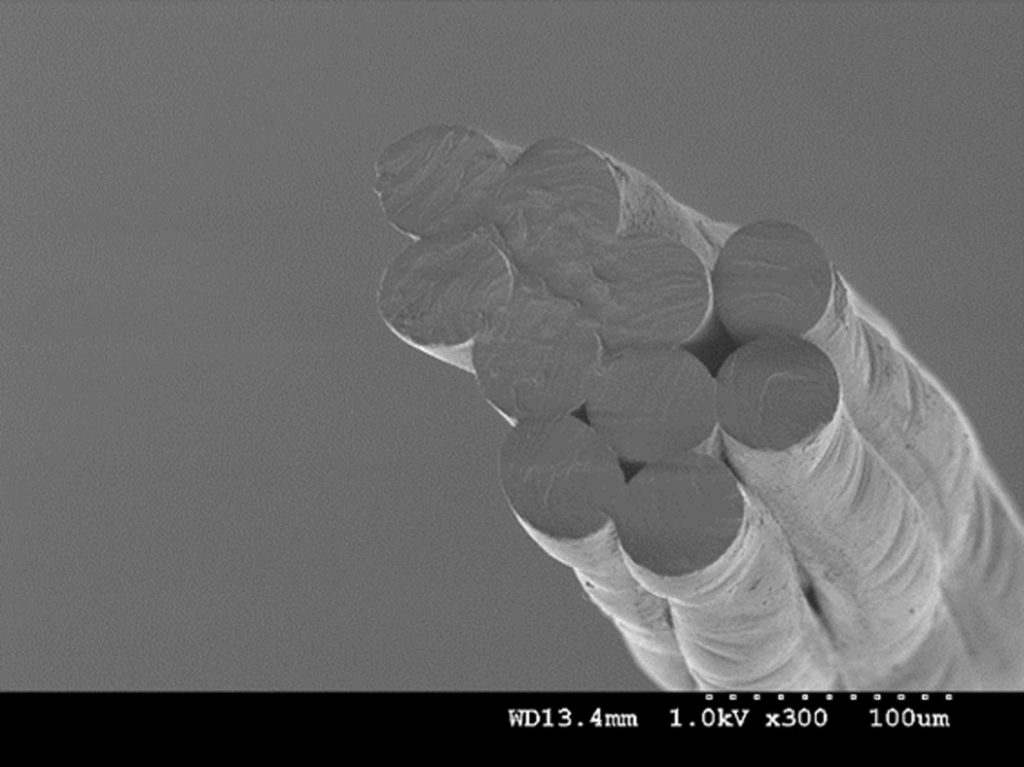

Dr Michelle Rae is proof, though, that it can be done, having undertaken her Ph.D. at Heriot-Watt University in Scotland in anti-embolism stockings (AES). Her work led to the discovery of a new yarn combination that solved the majority of pain points not successfully addressed by current AES on the market, and it abandoned the one-size-fits-all standard, establishing another unique selling position.

Rae has taken this development from Ph.D. in 2000 towards commercialization in a process where she acknowledges that the biggest challenge has been to find a team of experts with the complimentary skill set needed to bring the product to fruition.

It’s a big ask: enlisting IP experts and legal experts to draw up non-disclosure agreements and ensure patent applications and partnering with the right manufacturer that has the correct machinery. This alone can be a huge stumbling block, as manufacturers must tolerate significant downtime to carry out sampling during R & D. For a large brand, its name and potential order quantities may open doors, but start-ups do not have the same advantage.

Beyond the degree

The journey outlined by Rae has not been obvious or a single pathway. On completion of the degree’s practical work, she became a research associate at Edinburgh University, where the Ph.D. team secured funding from the Medical Research Council Confidence in Concept (MRC CiC), which enabled the development of the stockings and the evaluation of patients. Further funding was then secured to explore the commercial opportunities and assess the market with support from Dr. Lisa MacIntyre at Heriot Watt University, the Framework Knitters and Julian Ellis of Ellis Developments.

“The project stalled for a few years as the task of commercialization seemed too large to do alone, and as often is the case, funding ran out and life commitments took over,” says Rae. But the project got a second wind, “reignited by the passion of a local surgeon, who shared my belief and desire to deliver a better product to the patients in his care and beyond.”

Next steps? Further testing, sampling, achieving scale efficiencies, moving from prototyping machinery to commercial-level knitting machines, and finally delivering this improved medical product to hospitals in the U.K., as well as expanding internationally.

What comes across most strongly in both cases is the importance of building good relationships and a network that may need to expand far beyond the textile industry. There is a long-held argument that universities at graduate level should build in more courses and seminars addressing needed business skills, such as team building, project management and budget management. As Dr. Rae says, “the idea alone is not enough.”

Dr. Marie O’Mahony is an industry consultant, author and academic. She is a regular contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG