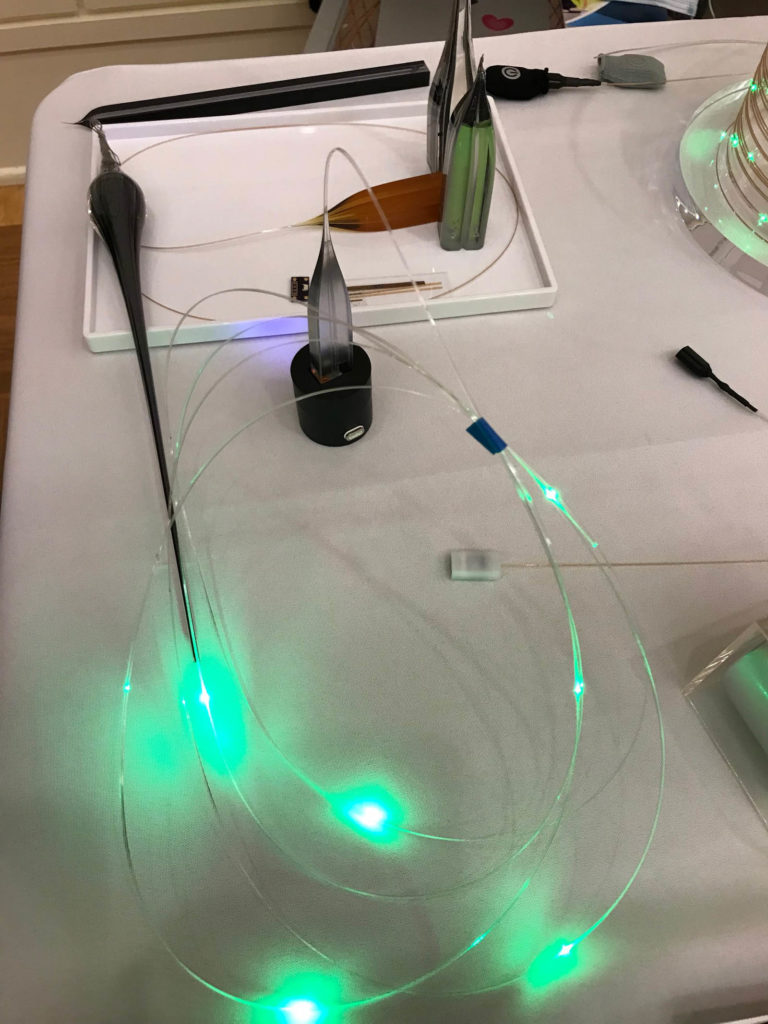

The Advanced Functional Fabrics of America (AFFOA) continues to be in the forefront of new developments in technologies for advanced textile systems. Michelle Farrington, vice president of strategic growth for AFFOA, provided several examples of projects with its industry partners.

The organization has been working with new textiles for wearable products, including carbon nanotube textile advancements; lightweight, waterproof, FR nylon; and bioderived polyethylene and synthesized spider silk textiles. It has also worked on the development of flexible electronics and fibers in composite cure monitoring; self-cleaning textiles; and environmental monitoring with undersea sensing.

Technology innovations have included soft robotics for hand rehabilitation; a haptic wearable device enabling music for people who are deaf; color change with photochromic inks; and new technology for 3D weaving. Farrington expects AFFOA to be working on sustainable materials and processing in future projects.

Shirts in space

Dr. Jan Beringer, senior scientific expert, Hohenstein Institute described its participation in the development of the SmartTex t-shirt for use on the International Space Station (ISS). Beringer said the work is “very much focused on the textile–human interface.”

The goal of the project be able to conduct low-power, lightweight, wireless experiments on the ISS, specifically to evaluate the impact of the space environment on the cardiovascular system.

Early in-flight sessions learned that astronauts were overheating when they exercised because of convection. Sweat simply doesn’t evaporate and disappear as it does on Earth.

Nevertheless, ““What we do on the space station has to have application here on earth,” he said. In both cases, monitoring and analysis of cardiovascular parameters is useful. In space, the continuous monitoring of vital signs on long-term missions is especially important, as is monitoring vital signs during critical situations, such as in activities outside of the spacecraft.

Long-term missions, such as to Mars, constitute future challenges. In these instances, there is no possibility of re-supply missions from Earth. On the space station, they’ll wear underwear for a week and a t-shirt for about two weeks, he says. “That’s life on the Space Station.”

On longer missions, astronauts will need special IVA garments for daily work and exercising. But how can anything be laundered, when water is limited to life support use? “I’m surprised that nobody has tried exposing fabric to the vacuum of Space,” Beringer says. “Maybe it all evaporates, and the fabric comes back clean. I don’t know.”

This, and other questions, remain to be answered. The shirt is part of the Wireless Compose-2 project, which is a collaborative effort among the German Aerospace Center (DLR), DSI Aerospace, Bielefeld University and Hamburg University of Technology.

A sensing sock

A group of educators and researchers from Mississippi State University (MSU) discussed their experience in developing wearable technology at MSU. Their work was an exercise in learning a productive way to collaborate, as well as navigating the pitfalls of developing wearables. As Assoc. professor Dr. Harish Chander said, “Athlete engineering has learned 10,000 ways not to build a wearable.

The project discussed involved creating a sensing sock to mitigate the danger of trip and slip falls. The sock is capable of capturing “very comprehensive movement of the wearer,” associate professor Dr. Harish Chander said. Chander’s area of expertise was initially in physical therapy. He began working on footwear, particularly to protect the foot, but then evolved into fall protection using sensing technology for posture control.

Charles Freeman, associate professor, emphasized the collaborative aspects of the work. “We really had to learn to speak each other’s language,” Freeman said. “I had to learn about biomechanics, and he [Chander] had to learn about fiber materials.”

Part of the process was getting objective feedback from the wearer because, “if they won’t wear it, the technology doesn’t matter,” so, it was important to collaborate to make it actually wearable,” Chander said.

“Wearable and human performance technology validation” was also discussed. According to David Sucier, research engineer, “The state of validation is somewhat unstandardized, I would say.”

Freeman added, “He’s a lot more politically correct than I am. It is the absolute wild wild west when it comes to smart fabrics materials. … Some people will say, ‘Well, we test against ourselves,’ but validation is critical and it’s important for academia to provide that testing against standards.”

The MSU team is working on methods to test smart fabrics in the same way that they test other textiles, “so we compare apples to apples,” says Freeman.

The sock technology they developed doesn’t prevent injury, they noted. It is, rather, injury mitigation by seeing data that may reveal a problem and having the information to correct it.

Freeman knows textiles, but “knows nothing about electronics,” he says. “The underlying thing is that we have to work collaboratively.” Chander agrees that what he’s done would have been impossible without his collaborative team, including many undergraduates. Erin Parker, graduate research assistant, moderated the panel.

Janet Preus is senior editor of Advanced Textiles Source. She can be reached at jlpreus@ifai.com.

TEXTILES.ORG

TEXTILES.ORG