New energy harvesting technologies show promise for successful commercialization.

by Marie O’Mahony, Ph.D.

Power and efficiency are not the only drivers of energy harvesting technology for e-textiles. Bulk, weight, flexibility, sustainability, ease of integration and scalability by no means complete the list, either. This is directing R&D in some spectacularly different directions, which in turn is opening further questions and possibilities. This discussion will highlight some of the new developments—and consider their potential for commercialization.

Textile-based coils

Examples of the diversity in current research are two projects looking at textile-based coils as a source of wireless power. At Purdue University and Massachusetts Institute of Technology (MIT) the focus is on the potential for omniphobic silk-based coils (OSCs) to be used in e-textiles as lightweight, stretchable power-receiving coils. The OSC microfibers are comprised of a novel silk-nanocarbon composite that combines the conductivity of the multiwall carbon nanotube and chitin carbon nanoflakes with the stretch offered by the silk fibroin. Scalability is key to success, and researchers are confident these have the potential to be sewn into a range of textiles to allow for the wireless powering of wearable technology, without compromising the handle of the fabric and wearer comfort.

At the German Institutes for Textile and Fibre Research Denkendorf (DITF) and the University of Stuttgart, scientists are also developing wireless charging by using coils with an important further step in the production of a textile inductive coil sensor. A silver-coated polyester yarn is used for the coil that is made of ten turns with a distance of 15mm that is stitched onto a non-conductive base fabric.

The fabric sensor in this form brings the possibility to monitor the wearer’s heart rate without the need for direct contact with the body. It is the change of the coil’s inductance relative to the change of the impedance inside the body that allows for the heart rate to be measured. A consideration beyond comfort, the coil sensor offers the possibility for a less intrusive and more accurate measurement to be given across a range of applications, such as competitive sports, extreme environment workwear or medical diagnostics.

Triboelectric energy

Kinetic energy has received only cautious attention until now, largely because of the difficulty inherent in quantifying it with a degree of accuracy. Recent developments in Triboelectric nanogenerators (TENGs) could change that. TENGs have the ability to convert mechanical energy into electrical power utilizing multiple sources, such as wind, rain and footfall.

The principles of triboelectrics can be traced back to 1757, when they were discovered by the Swedish physicist Johan Carl Wilcke. Derived from the Greek word “tribo,” which means “rubbing,” the energy harvesting occurs when materials are rubbed together resulting in friction and an exchange of electrons. The material aspect is crucial as the performance of the TENG is directly linked to the charge density of the contact surface, with nanotechnology particularly important to maximize this.

Researchers at Pohang University of Science and Technology (Kim et al.) have reported enthusiastically on the potential for lipid-based TENG in particular that have the additional benefit of being regenerative, which makes them more sustainable. Still at an early stage of development, the researchers say the material is comprised of four distinct layers: the charge-generating and charge-trapping layers, followed by the charge-collecting and finally the energy storage layers.

Looking to the future, the researchers see great potential for TENG-based sensing in the body that harness the subject’s own biomechanical motion to generate power.

Sweat energy

Human sweat is more usually associated with power exerted rather than a source of energy. At Nanyang Technical University in Singapore researchers have developed a battery using a hydrophilic polymer and small quantities of silver printed on a highly absorbent fabric that draws in sweat, triggering a reaction that results in power generation. The battery is restricted to use on areas of the body that produce the most sweat, such as the wrists.

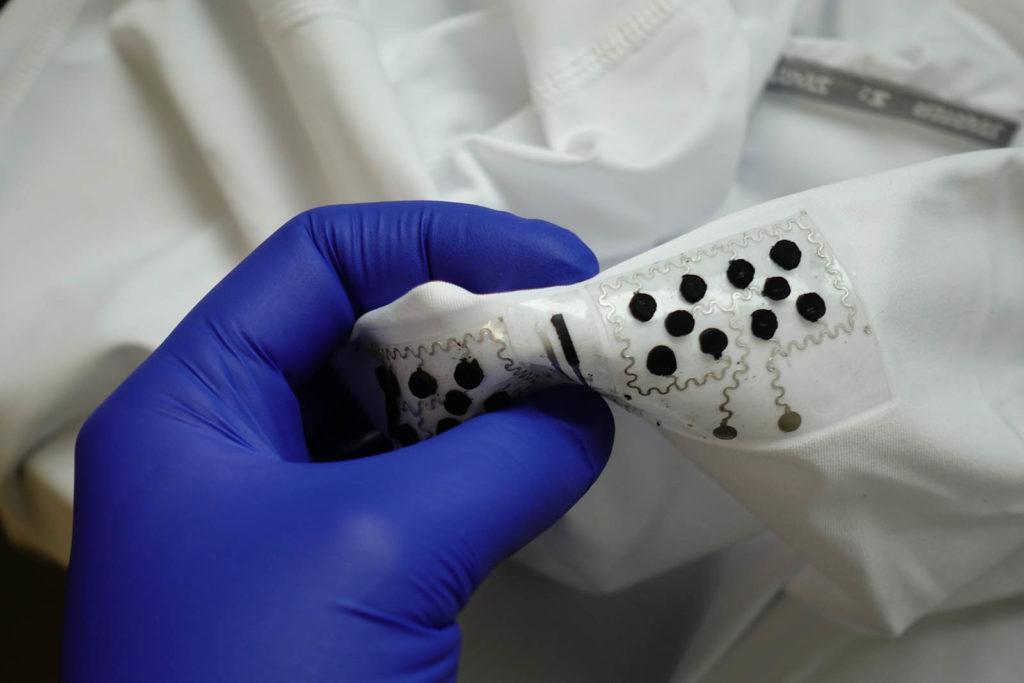

Researchers at the University of California San Diego (UC San Diego) are also harvesting energy from sweat, but they combine this with other sources such as movement. Researchers compare the approach of local energy harvesting to that of a city microgrid, even referring to it as a “wearable microgrid.” At the Center for Wearable Sensors at UC San Diego, a prototype shirt has been made to demonstrate how efficiently the system works in optimizing energy collection.

Sweat is collected from the chest area using biofuel cells equipped with enzymes ensuring electrons are swapped between lactate and oxygen molecules in order to generate electricity. Movement is captured from the sides of the body and arms as the person walks or runs, with triboelectric generators placed on the surface of the shirt harvesting this energy.

Storing the energy from both sources are supercapacitors located on the surface of the shirt around the chest. These then release the energy capable of powering small electronic devices. Incorporating a dual system increases efficiency and reliability while reducing the risk of running out of energy.

Soft and stretchable

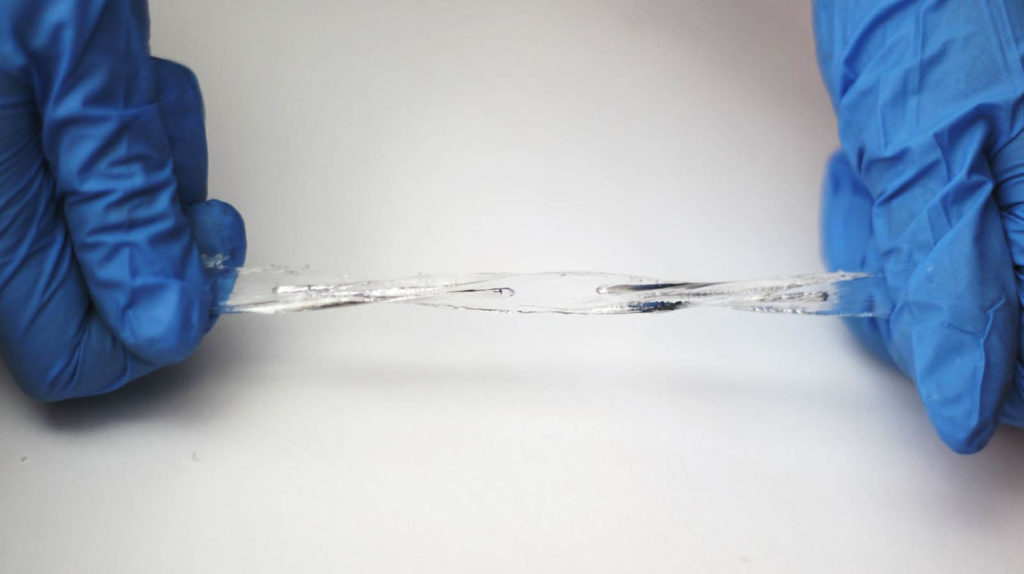

At the Department of Chemical and Biomolecular Engineering, North Carolina State University (NC State), Prof. Michael Dickey and his team have developed a soft, stretchable energy harvester using a liquid metal alloy (gallium and indium) encased in a hydrogel. The ions in the hydrogel react with the metal inducing a change in the latter, attracting charge and generating electricity.

Highly versatile, it can be stretched, deformed, and it works underwater. Like many of the developments mentioned, this is highly specialized, but that doesn’t mean that it’s developed in isolation. Professor Dickey’s university web page lists some of the application areas his group’s research looks to: “patterning, 3D printing, stretchable/soft electronics, self-folding, actuating of soft robotics, wearable electronics, energy harvesting devices, reconfigurable circuits and microfluids.” Such diversity cannot but create a crossover of ideas and a fertile ground for innovation.

Dr. Marie O’Mahony is an industry consultant, author and academic. She the author of several books on advanced and smart textiles published by Thames and Hudson and visiting professor at the Royal College of Art, London. www.linkedin.com/in/marie-o-mahony-94776836

TEXTILES.ORG

TEXTILES.ORG