Filtration plays an important role in purifying and decontaminating two life necessities: water and air. As awareness of the related health issues has increased, the demand for protection from air-borne pollution and disease has also increased. Dr. Fabrice Karabulut, RD & Implementation Scientist with Revolution Fibers, Auckland, N.Z., offers an explanation into the unique and enhanced capabilities that electrospun (ES) nanofibers can provide when used as an active layer in face masks.

When compared to common melt-blown (MB) filters, ES nanofibers were found to provide better protection against air particles, bacteria, and viruses such COVID-19, the company says. The filtration mechanisms for MB filters are highly dependent on electrostatic deposition. This means that when the electrostatic charge is lost, the filtration efficiency drops. Such electrostatic charges can be lost due to moisture in the environment. The moisture-capturing nature of MB N95 masks have been reported to cause headaches and create a favourable environment for viruses and bacteria, Karabulut says.

Due to its versatility and ability to use a wide variety of polymers, ES nanofiber production rates are approaching that of the conventional MB process. There has been a recent interest in green electrospinning, which involves water-based solutions.[6] Only a few academic groups and Revolution Fibers have investigated aqueous solution electrospinning and other methods of fabricating green electrospun nanofibers.

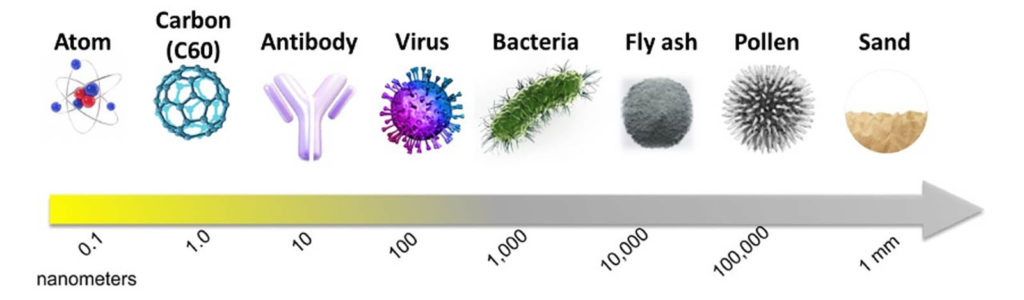

NF fabrics produced by electrospinning have attracted attention for use in filtration partly because the diameter of nanofibers are 10-100 times smaller than that of conventional MB microfibers. The higher surface area in nanofibers induces better filtration efficiency, largely because surface interaction is the dominant driving force in air filtration. In addition, the company says that the electrospinning process offers opportunities to fine tune the surface functionality through polymer chemistry, blending and nanofiller incorporation during processing, which responds to the variety of ways that particles are captured via filtration.

The current pandemic has amplified the need for masks to be reusable but retain effectiveness. A study was performed on the reusability of MB and ES NF filters when cleaned with ethanol (sprayed and dipped).

The results showed that MB filters are only effective for single use due to the steep reduction of filtration efficiency after ethanol cleaning (to ~ 64 percent). This is because the electrostatic charge of MB filter is lost when cleaned, leading to a dramatic drop in performance. MB filters lose static electricity when exposed to water and moisture, diminishing their filtering effect to almost half the original performance. ES nanofiber filters can be successfully reused multiple times after cleaning with ethanol, the company found, as the filtration efficiency remains consistent (~97-99 percent).

Source information: “Melt-Blown Fibers vs Electrospun Nanofibers as Filtration Media,” a white paper by Dr. Fabrice Karabulut, RD & Implementation Scientist with Revolution Fibers, Auckland, New Zealand.

TEXTILES.ORG

TEXTILES.ORG