Researchers working at the University of Bordeaux/INSERM have created yarns of human cells from sheets of cell-assembled extracellular matrix, or CAM. The findings, reported in www.materialstoday.com, are a significant achievement because the CAM can be mass-produced for clinical applications, including tissue engineering.

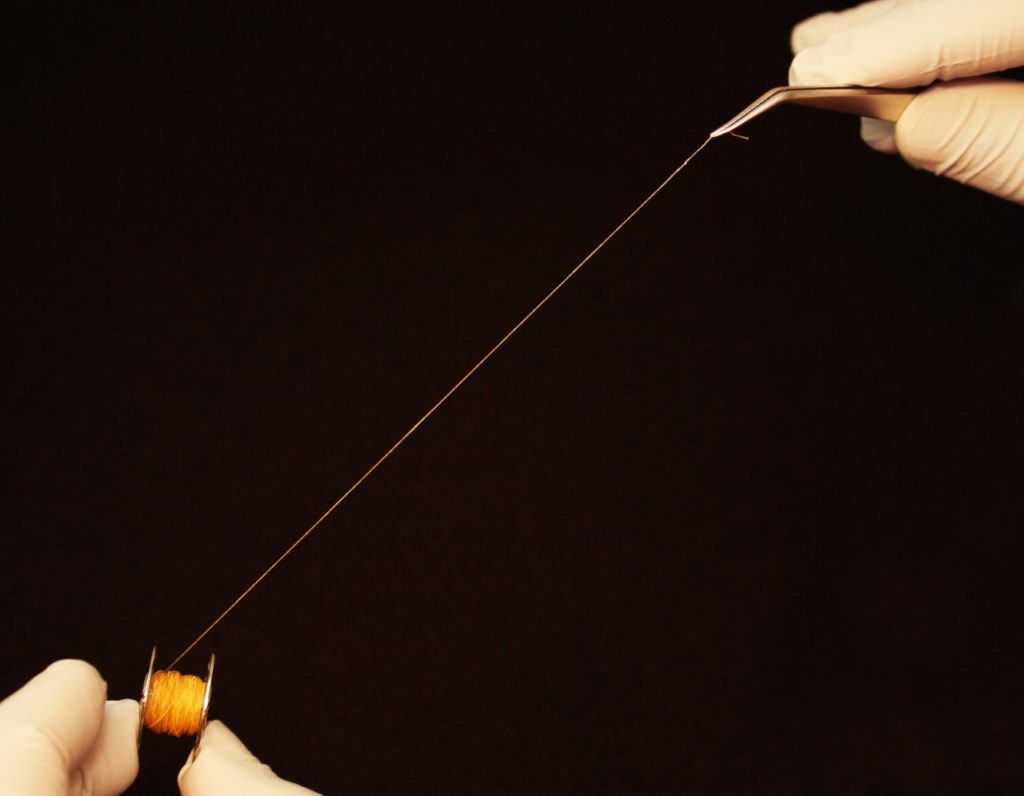

However, the process is complex and the usefulness of sheets for creating different shapes is limited. “We make yarn by cutting the CAM sheet into ‘ribbons’ that can be used directly or twisted into ‘threads’ [with] slightly different mechanical properties,” says Nicolas L’Heureux, University of Bordeaux/INSERM, who led the research.

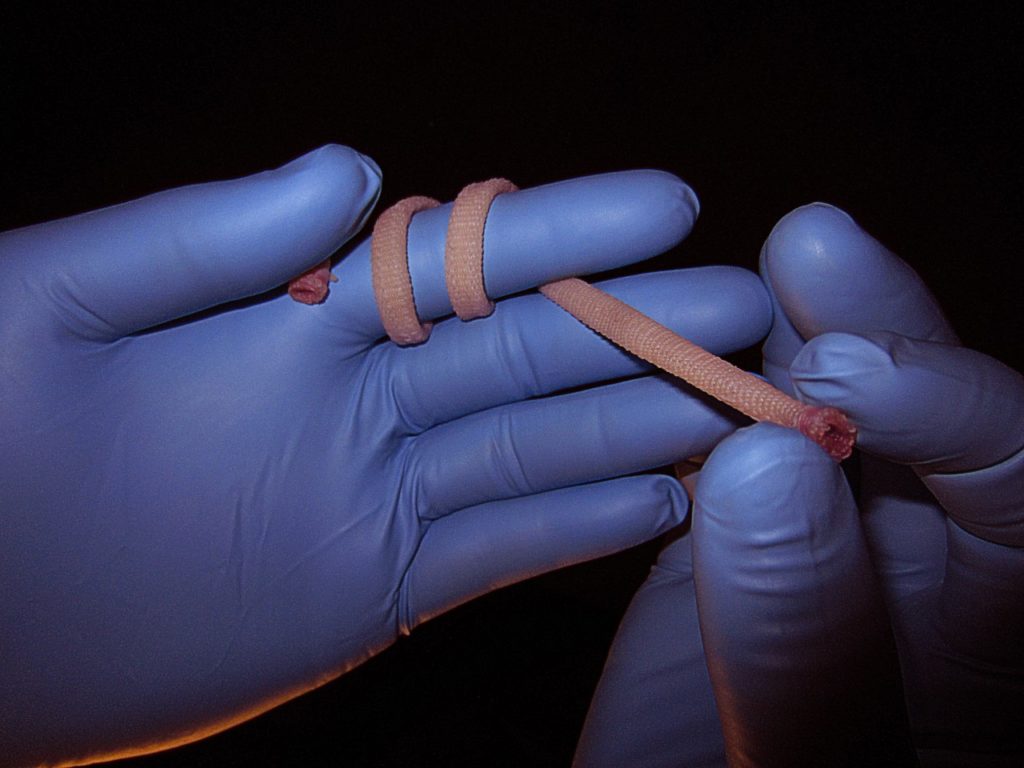

The yarns, which can be 2-10mm wide and up to 3m long, can be used as they are as simple sutures for wound repair, or they can be woven, knitted, or braided into almost any shape. Multiple yarns can be twisted together to create thicker, stronger yarns if different mechanical properties are needed. The yarn can be simply dried, stored frozen, and rehydrated when needed, the researchers report.

“Textile assembly can be automated so tissue production will eventually be much faster, easier, and cheaper than with a sheet-based approach,” says L’Heureux. “Since the approach is very versatile, it can address many applications.”

Medical textiles currently used for suturing wounds or as vascular grafts for blood vessel repair, for example, are typically made from permanent polymers such as GORE-TEX® or biodegradable materials such as polyglycolic acid or collagen. Synthetic materials tend to be recognized by the body’s immune system, giving rise to an inflammatory response, while biodegradable materials can lose strength too rapidly for more demanding applications. Tissue engineering is particularly dependent on synthetic biomaterials as scaffolds for cells to populate or regrow on, but a completely biological alternative would be highly desirable.

“For decades, we have been able to grow human cells in the lab,” says L’Heureux. “My team has been working for a long time on getting normal human cells to produce actual tissues. In the right conditions, a thin but strong sheet of human collagen (and other important proteins) is assembled by the cells.”

As an example, the researchers fabricated a vascular graft from woven ‘human textile’ with properties that surpass clinical requirements. Unlike synthetic material, these fully ‘bio’ materials could be readily accepted by the body without eliciting an immune response.

TEXTILES.ORG

TEXTILES.ORG