Sustainability issues leap to the forefront in creating new synthetic fibers.

by Ericka Ford, Ph.D.

Robert Hooke’s 1664 belief—that plants eaten by the silkworm could spin into a silk alternative—was an oversimplification of the biological processes that ultimately allowed the food satiated silkworm to spin silk. Nevertheless, the timely invention of the regenerated cellulosic fiber, Rayon, sustained the female apparel and technical textile industries that were later threatened by restrictions imposed because of the WW II. The luminescent sheen of these fibers inspired the label “RAY-on” after the brilliance of the sun and was, perhaps, a personification of hope for the synthetic fibers industry, which began with the introduction of viscous rayon into commercial markets in the early 20th century.

The need for sustainable synthetics

The synthetic fiber industry that was born of the mechanized spinning of resins has now become a global threat to the beauty of our lands and aquatic ecosystems, especially as the production of fibers out-pace the degradation of natural fibers and the effuse of nondegradable synthetics increases. How are we to stop this global pollution? If our food sources are dining on microfibers and plastics, are we, as well?

We still have choices for the responsible consumption and recycling of textile products. And perhaps, Hooke’s principle will spark another revolution, where textile markets are flooded with biodegradable synthetics whose physical properties compete with the most popular synthetics. Much more than the manipulation of performance properties, we must spin these fibers by responsibly harvesting biorenewable materials and spinning them through green manufacturing technologies. Further, manufacturers must ensure that the durability of biobased, biodegradable materials are on par with synthetics.

The opportunities are greater for polymer scientists and textile fiber engineers to come together, and it is increasingly important. Polymer science was born from the disciplines of chemistry, physics and biology—not truly finding a home in any of them—from which emerged this area of specializations. There is now, more than ever, an opportunity for fiber scientists and engineers to embrace their parent discipline of polymer science to innovate the textile fiber industry through green manufacturing. The careful consideration of biorenewable resins and processing steps to minimize the environmental footprint of the synthetic fiber industry is needed for a global solution to microfiber pollution.

Sources of biorenewable material

So, let’s talk about sources of biorenewable material. Does it all have to come from harvested softwoods and cotton? And what about nonedible agricultural waste? Can society make better use of cultivated crops so that waste by-products are used in value added products? Straw, husk and the stems of crops are waste by-products that also comprise the gift of pre-synthesized polymers. The use of these biorenewable waste by-products equates to a more efficient use of our agricultural lands and water resources. The potential for new innovation is endless.

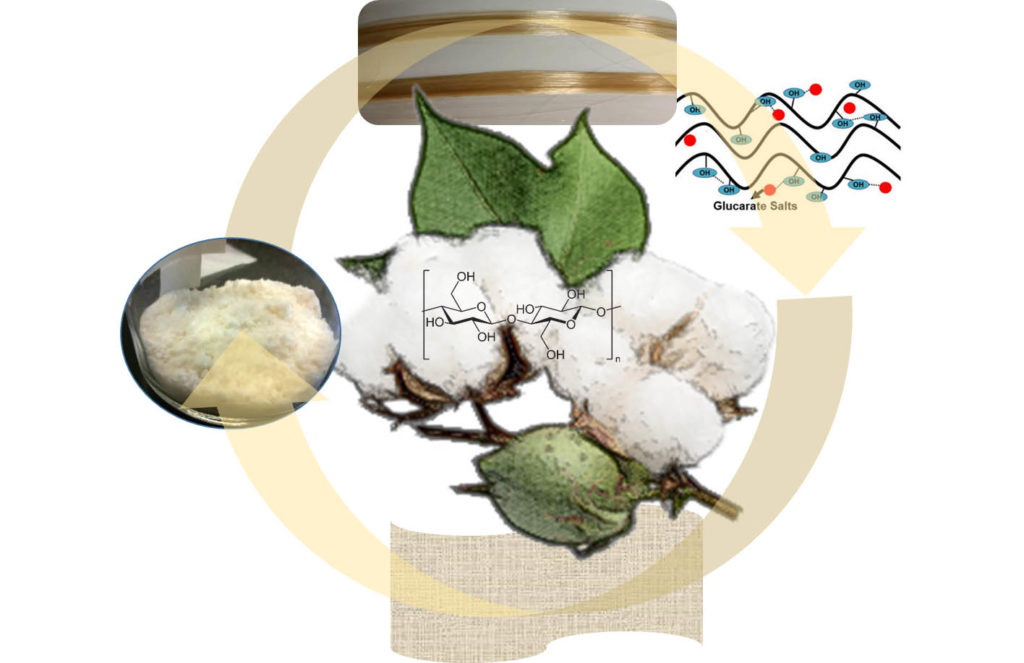

The Ford research team within the Wilson College at North Carolina State University (NC State) is tackling this challenge through industrial collaborations and research in the areas of regenerated fibers and biobased additives for fiber processing. For example, cotton pulp was recycled from clothing. These pulps were produced by Tyton BioSciences through green hydrothermal processing technologies and later regenerated into spun cellulosic fibers. The addition of glucaric acid, a green antiplasticizing agent, was shown to drastically increase the dry modulus by 4.8 times (versus 129 g/denier for fibers without additive) and wet modulus by 1.75 (from 80 gram/denier).

The technique of antiplasticization is utilized by plastic engineers to improve the modulus and tensile properties of molded plastics and films, but is studied to a lesser extent than plasticization, which improves the flow behavior of polymers for processing—especially when it comes to fiber manufacturing! BPA- bisphenol A- is one of the more infamous antiplasticizers, due to its discontinuation in food containers and ban from plastics used by infants and toddlers. Now, the popular designation ‘BPA-free’ is marketed on plastics in response to consumers concerns about their carcinogenic nature.

The fiber industry has been quiet on identifying antiplasticization, although examples of it can be found. It is possible to increase the modulus of textile fibers through the incorporation of these additives that co-crystallize with matrix polymer through secondary bonding. These interactions occur between polymer and glucaric acid (a six carbon di-carboxylic acid having four -OH groups) under thermal drawing.

Industrial biotech company Kalion Inc., based in Milton, Mass., synthesizes glucaric acid organically using green fermentation technology. The extent of antiplasticization through glucaric acid addition is specific to polymer type, levels within the polymer, and conditions of processing. The molecular structure of glucaric acid also reveals that not all accounts of antiplasticization must involve aromatic polymer, but historically small, aromatic molecules were used as antiplasticizers.

Antiplasticizers in nature

Nature also provides an abundant source of aromatic antiplasticizers, which are found in the cell walls of plants. This cement of plant life is called lignin. During pulp and paper processing, lignin is extracted from wood cellulose, but non-woody plants also contain lignin. Many challenges have come with the spinning of lignin into high value-added products. These include how to spin it into commercial fibers, improving its compatibility with other resins to create bio-synthetic hybrids of reasonable strength, and actually achieving antiplasticization at high loadings of lignin.

Through scientific approaches in polymer spinning, the Ford team has achieved loadings of 20-50 percent lignin within biosynthetic fiber, without sacrificing their tensile modulus, but rather improving it. Our long-term goal is to work with industry to bring forward the realization of carbon fiber from mostly lignin fibers.

The synthetic fiber industry was inspired by nature, but its continuation is motivated by the protection of nature. The textile fiber industry of the 21st century is ripe to adopt raw materials from organic and previously discarded materials sources. Realization of the circular textile economy will also require industry and consumers to sort their contributions of recyclable material. As lofty as these goals may seem, innovations in the regenerated fiber industry all go back to the polymer science.

Dr. Ericka Ford is an assistant professor within the Wilson College of Textiles (COT). She holds a joint appointment in the Department of Textile Engineering, Chemistry and Science and The Nonwovens Institute at North Carolina State University.

TEXTILES.ORG

TEXTILES.ORG