Producing fabrics that perform all the functions desired, while retaining the best characteristics of fabric is no easy task. Two groups of researchers at Drexel University, Philadelphia, Pa., believe they have a solution by improving a basic element of textiles: yarn.

One group is leading the development of industrial functional fabric production techniques, and the other is a pioneer in the study and application of one of the strongest, most electrically conductive super materials in use today. By adding technical capabilities to the fibers that give textiles their character, fit and feel, the team has shown that it can knit new functionality into fabrics without limiting their wearability.

In a paper recently published in the journal Advanced Functional Materials, the researchers, led by Yury Gogotsi, Ph.D., Distinguished University and Bach Professor in Drexel’s College of Engineering, and Genevieve Dion, a professor in Westphal College of Media Arts & Design and director of Drexel’s Center for Functional Fabrics, showed that they can create a highly conductive, durable yarn by coating standard cellulose-based yarns with a type of conductive two-dimensional material called MXene.

Taking on the challenges

“Current wearables utilize conventional batteries, which are bulky and uncomfortable, and can impose design limitations to the final product,” they write. “Therefore, the development of flexible, electrochemically and electromechanically active yarns, which can be engineered and knitted into full fabrics, provide new and practical insights for the scalable production of textile-based devices.”

The team reported that its conductive yarn packs more conductive material into the fibers and can be knitted by a standard industrial knitting machine to produce a textile with top-notch electrical performance capabilities. This combination of ability and durability stands apart from the rest of the functional fabric field today.

“Some of the biggest challenges in our field are developing innovative functional yarns at a scale that are robust enough to be integrated into the textile manufacturing process and withstand washing,” Dion said. “We believe that demonstrating the manufacturability of any new conductive yarn during experimental stages is crucial.

“High electrical conductivity and electrochemical performance are important, but so are conductive yarns that can be produced by a simple and scalable process with suitable mechanical properties for textile integration. All must be taken into consideration for the successful development of the next-generation devices that can be worn like everyday garments.”

Dion, a pioneer in wearable technology, has drawn on her background in fashion and industrial design to produce processes for creating fabrics with new technological capabilities. Her work has been recognized by the U.S. Dept. of Defense, which included Drexel and Dion, in its Advanced Functional Fabrics of America effort to make the country a leader in the field. She teamed with Gogotsi, a researcher in the area of two-dimensional conductive materials, to approach the challenge of making a conductive yarn that would hold up to knitting, wearing and washing.

Gogotsi’s group was part of the Drexel team that discovered the highly conductive two-dimensional materials called MXenes in 2011 and have continued to explore their exceptional properties and applications. His group has shown that it can synthesize MXenes that mix with water to create inks and spray coatings without any additives or surfactants — a revelation that made them a natural candidate for making conductive yarn that could be used in functional fabrics.

“Researchers have explored adding graphene and carbon nanotube coatings to yarn, our group has also looked at a number of carbon coatings in the past,” Gogotsi said. “But achieving the level of conductivity that we demonstrate with MXenes has not been possible until now. It is approaching the conductivity of silver nanowire-coated yarns, but the use of silver in the textile industry is severely limited due to its dissolution and harmful effect on the environment. Moreover, MXenes could be used to add electrical energy storage capability, sensing, electromagnetic interference shielding and many other useful properties to textiles.”

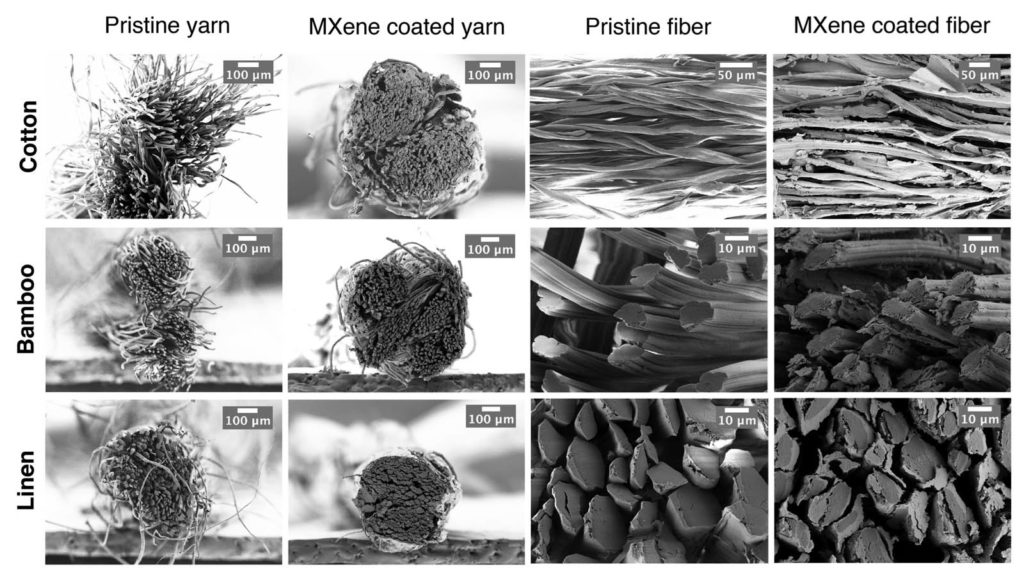

In its basic form, titanium carbide MXene looks like a black powder. But it is actually composed of flakes that are just a few atoms thick, which can be produced at various sizes. Larger flakes mean more surface area and greater conductivity, so the team found that it was possible to boost the performance of the yarn by infiltrating the individual fibers with smaller flakes and then coating the yarn itself with a layer of larger-flake MXene.

The team created the conductive yarns from three common, cellulose-based yarns: cotton, bamboo and linen. They applied the MXene material via dip-coating, which is a standard dyeing method, before testing them by knitting full fabrics on an industrial knitting machine.

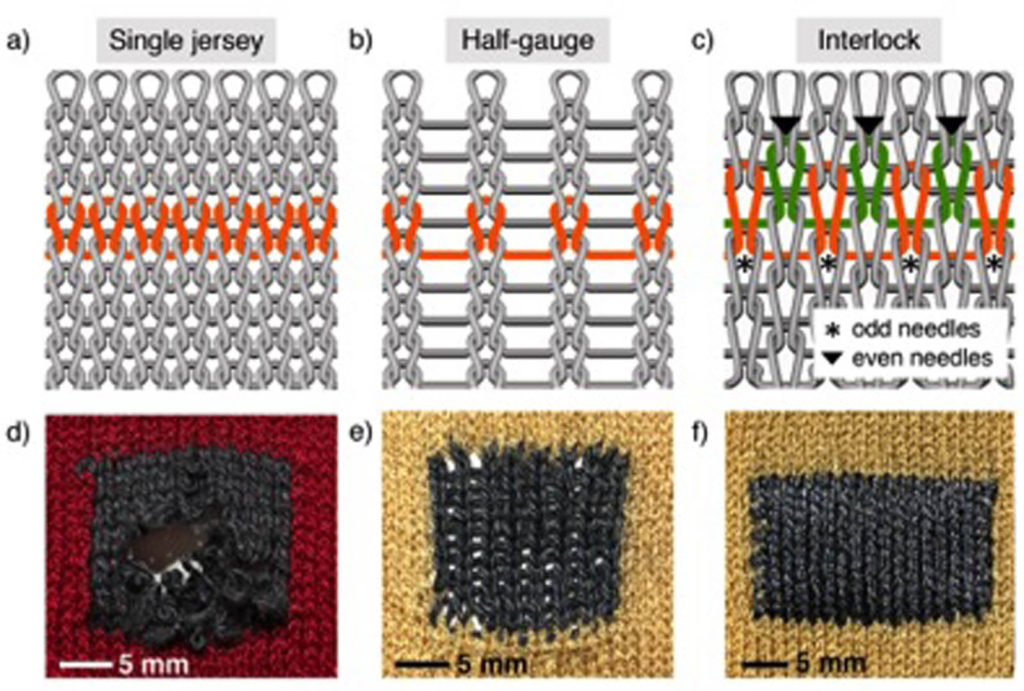

Each type of yarn was knit into three different fabric swatches using three different stitch patterns — single jersey, half gauge and interlock — to ensure that they are durable enough to hold up in any textile. “The ability to knit MXene-coated cellulose-based yarns with different stitch patterns allowed us to control the fabric properties, such as porosity and thickness for various applications,” the researchers write.

To put the new threads to the test in a technological application, the team knitted some touch-sensitive textiles — the sort that are being explored by Levi’s and Yves Saint Laurent as part of Google’s Project Jacquard.

Not only did the MXene-based conductive yarns hold up against the wear and tear of the industrial knitting machines, but the fabrics produced survived a battery of tests to prove its durability. Tugging, twisting, bending and washing, did not diminish the touch-sensing abilities of the yarn, the team reported.

But the researchers suggest that the ultimate advantage of using MXene-coated conductive yarns to produce these special textiles is that all of the functionality can be seamlessly integrated into the textiles. So instead of having to add an external battery to power the wearable device, or wirelessly connect it to a smartphone, these energy storage devices and antennas would be made of fabric as well, an integration that, though literally seamed, is a much smoother way to incorporate the technology.

Using conductive yarns also means that a wider variety of technological customization and innovations are possible via the knitting process. For example, “the performance of the knitted pressure sensor can be further improved in the future by changing the yarn type, stitch pattern, active material loading and the dielectric layer to result in higher capacitance changes,” according to the authors.

Dion’s team at the Center for Functional Fabrics is already putting this development to the test in a number of projects, including collaboration with textile manufacturer Apex Mills — one of the leading producers of material for car seats and interiors. And Gogotsi suggests the next step for this work will be tuning the coating process to add just the right amount of conductive MXene material to the yarn for specific uses.

“With this MXene yarn, so many applications are possible,” Gogotsi said. “You can think about making car seats with it so the car knows the size and weight of the passenger to optimize safety settings; textile pressure sensors could be in sports apparel to monitor performance, or woven into carpets to help connected houses discern how many people are home. Your imagination is the limit.”

The work was supported by the U.S. Department of Energy.

TEXTILES.ORG

TEXTILES.ORG