Textiles are part of a larger, more comprehensive sustainability picture.

Sustainability may be understood as a way to judiciously consume resources while leaving, or even enhancing, the availability of resources for future generations. The term “sustainability” has developed a powerful vibe that impacts our society in general and the business community, specifically.

Environmental contamination stresses the human population, as well as animal and plant biodiversity. It is significant that recognition of these dynamics has prompted governments to take sustainability seriously and move to regulate the use of certain products.

In October 2018, the European Parliament voted to ban certain single-use plastics by 2021. According to the EU parliament, the main reason behind the ban is marine pollution, which affects biodiversity. Similarly, certain states in India have banned the use of thin, polyethylene single-use bags.

Articulating the issues

Sustainability means different things to different folks—conserving resources, use of natural materials, use of alternate energy sources and use of green technologies are some examples. Sustainability for many rests on the 3 E’s: environment, economics and energy. In other words, one must be cognizant of environmental sustainability, economic viability and energy-process efficiency. If projects and products are planned with careful consideration of the 3 E’s, we may preserve the world in a better way.

Professor Sridhar Narayanan, Chennai, India-based educator and a corporate social responsibility advocate, is of the opinion that those with the power and means to do so, have the highest responsibility to ensure that our acts are supportive and responsible towards enhancing a better environment for future generations.

Professor Ronald Kendall, a former president of the Society of Environmental Toxicology and Chemistry says that with the increasing global human population and demand for food, fiber and fresh water, the issue of toxic chemical pollution continues to be a challenging concern as we seek to provide the scientific data to enhance sustainability of resources for both humans and biodiversity on the planet.

The advanced textiles sector

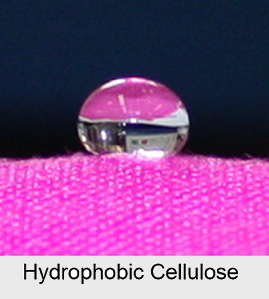

While the industrial fabrics sector is heavily dependent on synthetic fibers, the industry is exploring the use of alternative fibers such as hemp, cotton and polylactic acid (PLA) fibers to develop products. Still to be sorted out is the cost issue in using new and emerging raw materials. In addition to the increased awareness on alternative fibers, new processes are being explored, including atmospheric plasma techniques to impart new surface finishing effects, supercritical carbon dioxide, lasers, and phase-changing materials. The plasma processing techniques have become commercial with wide-width machines currently available.

The advanced textile industry has adopted the use of atmospheric pressure plasma technology to re-shape their manufacturing processes for enhanced sustainability, economy and efficiency. The use of continuous atmospheric plasma technology for improving the uptake and adhesion of dyes, inks, coatings and adhesives has replaced many complex and polluting chemical processes in the industry. Specifically, the use of water, harmful chemicals and energy is significantly reduced in comparison to conventional textile treatment methods, according to Rory Wolf, business unit manager of ITW Pillar Technologies, Hartland, Wis.

The cotton sector is also playing its part in enhancing its sustainability goals. A 10-year goal statement has been released by the United States cotton sector, which is making good progress towards achieving these goals, including reducing water and chemical usage, decreasing greenhouse gas emissions and decreasing energy use by 15 percent. These initiatives would help to meet the standards set in the Paris Climate Agreement of 2015.

While initial investments may be slightly higher towards green approaches, in the long term being sustainable is more profitable, says Kater Hake, vice president for agricultural and environmental research for Cary, N.C.-based Cotton Inc. According to Dr. Hake, industries such as the cotton and textiles sectors must meet the requirements of consumers with regards to their expectations that may vary in fashion and aesthetic senses, environmental considerations and the price they are willing to pay to gain additional value-added benefits.

An important aspect that needs attention is relaying the benefits of sustainability to the practitioners and consumers. Farmers have had an impact in preserving and protecting our natural resources. Over the last 30 years, we have significantly reduced our usage of irrigation water, energy and land, and have reduced greenhouse gas emissions. It is vital that we continue to conduct research that supports further efforts in sustainability, says Steve Verett, executive vice president of Lubbock, Texas-based Plains Cotton Growers Inc.

Integrated pest management and Bt [insect-resistant] technology are critical components of the sustainability of the cotton ecosystem. Adoption of Bt has reduced insecticide use substantially over the last two decades, according to Suhas Vyavhare, extension cotton entomologist at the Lubbock-based Texas A & M AgriLife Research and Extension Center.

Suggestions for the textile industry by seasoned industry consultants offer valuable insights. Kanti Jasani, president of Harrisburg, Pa.-based Performance and Technical Textile Consulting, says that selection of proper raw materials is an important step towards achieving sustainability goals and he emphasized the importance of training. He compared it to the restaurant business that focuses on consumers’ tastes and needs.

“It is like developing and following a cooking recipe, which can be different depending on taste, the part of the world, and customs. Using more-than-needed ingredients makes the food tasteless or inedible,” Jasani says.

Regarding processing efficiencies in the dyeing and finishing sectors, Jasani suggested using a short liquor ratio, adopting waterless, reverse flow, continuous dyeing, and adopting proper process steps with optimum process ingredients and resources like water, chemicals and energy. Lastly, adopting proper automation and control systems can also be a large part of success, according to Jasani.

It is clearly evident that proper communication among stakeholders, getting buy-in from technology adopters, and delivering cost-effective, sustainable products to bring consumers on board are vital for the growth of the advanced textiles sector.

The passion for leaving a better world to our future generation was evident with Prof. Narayanan, who says, “We the humans many times act selfishly towards the wants. It is our responsibility to demonstrate, practice the acts of sustainability in every way we think, and make it a way of life, which was very much a part of ancient traditions across the world.”

Seshadri Ramkumar, Ph.D., is the director of the Nonwovens and Advanced Materials Laboratory, Texas Tech University, and a frequent contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG