How textile-based biomaterials and medical devices support human body repair.

Textile-based biomaterials or biotextiles have the longest history in the field of biomaterials. In ancient China and Egypt as far back as 2000 B.C., natural fibers such as linen, silk, bark, horsehair and dried guts were used as suture materials for wound closure. The introduction of steel wire and synthetic fibers such as polypropylene, nylon and polyester during and after World War II brought the first revolution of medical textiles and greatly expanded the chemical composition of textile-based biomaterials beyond natural sources.

Surprisingly, cotton, the most desirable natural fiber in apparel and traditional textile-based products, has no role in the modern implantable medical textile field, probably due to the lack of desirable biological and mechanical properties to meet the very high safety standard inside a biological environment like the human body. Among the natural fibers, silk is the only one that has been successfully adopted in the modern implantable medical textile field.

Textile structures

Owing to their precisely controlled manufacturing processes, as well as their uniform and reproducible properties, synthetic fibrous biomaterials have received a great deal of attention from the medical industry, surgeons and researchers. However, the basic textile structures, such as braided, twisted, knitted, woven, and nonwoven, has not kept up the much faster pace of development and advancement of new materials.

The only meaningful textile structure advancement that has been biomedically significant is electrospun fibrous membranes, particularly those nanofiber-sized membranes as scaffolds for tissue engineering and regeneration. That means most of the research and development activities have focused on new materials, particularly absorbable or biodegradable materials, instead of creating a new textile structure.

The advancement of textile-based biomaterials made another major breakthrough in the early 1970s after the successful introduction of two synthetic absorbable wound-closure biomaterials that are aliphatic polyester based: Dexon and Vicryl. These synthetic absorbable fibers are made from absorbable aliphatic polyesters like polyglycolic acid, poly-L-lactic acid, and poly-4-hydroxybutyrate (produced by microorganisms, TephaFlex®) and their copolymers.

The availability of this new class of absorbable aliphatic polyester-based materials opened a new chapter for medical textiles, particularly in wound closure, cardiovascular implants, body wall repair, and tissue engineering and regeneration. Today, surgeons can choose among a large number of textile-based biomaterials with various chemical, physical, mechanical, textile structural and biological properties for their specific clinical applications.

Distinctive and diverse

Textile-based biomaterials are different from other biomaterials largely in their physical form and anisotropic mechanical behavior. They are the only class of polymeric biomaterials other than hydrogels that could have a wide range of three-dimensional porous structures. The four most widely used textile structures as biomaterials are woven, knitted, nonwoven and braided. Within each of these four classes of textile structure, there are many other variations such as weft knit vs. warp knit.

These structural features and the wide range of structural possibilities and mechanical strength orientation provide the unique advantages for their numerous applications in biomedical fields, such as

1. The requirement of tissue ingrowth for fastening implantable medical devices like the suture ring of an artificial heart valve,

2. The requirement for integration with surrounding tissues for achieving better tissue biocompatibility like vascular grafts,

3. The requirement of large surface and pore area in a 3D structure like tissue engineering scaffolds,

4. The requirement to fill void space and provide mechanical support like surgical meshes for body wall repair,

5. The requirement to carry physiological force anisotropically, as in wound closure and tendon/ligament prostheses, and

6. The requirement of mechanical strength, as with fiber and fabric-reinforced composites in a variety of surgical implants, such as total artificial hearts, penile implants and bone fixation devices.

Aside from modern textile-based implants, medical textiles have been used for a far longer history outside the human body as hospital linens, surgical gowns and drapes, anti-embolism stockings, the reinforced components of casts and other uses. The focus in this article is on the use of implantable medical textiles because they are indispensable for the repair and reconstruction of the human body, particularly in the areas of wound closure, cardiovascular implants, and surgical meshes for body wall repair.

Implantable medical textile products are also more critical than those disposable medical textile products used outside the human body. Furthermore, implantable medical textile products require great technical sophistication and demand because of the safety, biological complexity and challenges of the human body, in addition to regulatory hurdles. Among these three areas of application, the textile biomaterials for wound closure are especially important, not only because they are used in virtually every surgery for the fastening of surgical implants and closure of wounds, but also textile-based wound closure biomaterials have a historical tie to traditional textile materials for non-medical uses; silk, polyester, nylon and polypropylene are examples.

Suture materials

Wound closure biomaterials are generally divided into three major categories: suture materials, tissue adhesives and staplers. Only the suture materials are in textile form. They also have the largest market share and receive the most research and development attention. They are also the most widely used in wound closure for surgery. The world market size of sutures is expected to be about $4.40 billion by 2021, a 27 percent increase from $3.46 billion in 2016.

A suture by definition is a strand of textile material, natural or synthetic, used to ligate blood vessels and to sew tissues together. It consists of a fiber with a metallic needle attached at one of the fiber ends. An ideal suture should:

• Handle comfortably and naturally.

• Show minimum tissue reaction.

• Have adequate tensile strength and knot security.

• Be unfavorable for bacterial growth and easily sterilized.

• Be nonelectrolytic, noncapillary, nonallergenic and noncarcinogenic.

• Have low memory effect for easy handling and better knot security.

Suture materials are commonly classified by absorbability or biodegradability in biological tissues, size, physical configuration (monofilament vs. multifilament, braided vs. twisted), and type of coating materials used not only to facilitate proper handling during wound closure, but also to provide additional functionality such as antimicrobial properties.

Coating materials mainly apply to multifilament, braided suture fibers for not only an easier passage through tissues with less resistance during wound closure, but also for reducing wound infection, since suture fibers, particularly those multifilament braids, are a source where bacteria can hide.

Antimicrobial coatings on medical textiles in general have become an increasing important requirement for the purpose of reducing infection, particularly at wound sites. Surgery-related infection, one of the most frequently reported types of hospital-acquired infection, represents about 17–19 percent of healthcare-acquired infections, which puts patients at increased risk.

Two types of antimicrobial coatings have been FDA-approved for use in both implantable and non-implantable medical textiles: triclosan and N-halamine-based. The former is a broad-spectrum antimicrobial agent that has been used for 40 years, and is the most common type for antimicrobial sutures. The N-halamine family is mainly for non-implantable medical textile use, such as in patient gowns and surgical drapes.

Silver or its nanoparticles have also been examined as the antimicrobial coating material on medical textile products, but no commercial implantable medical textile products with a silver or silver nanoparticle coating are available at this stage, probably due to the cytotoxicity concern of silver and silver nanoparticles.

Suture materials have vast differences in chemistry, physical/mechanical properties, and biological characteristics. Most of those common fibers used for conventional textiles and apparel purposes (nylon 6,6 or 6, aromatic polyester, polypropylene, Gore-Tex or silk) have been adopted for non-absorbable suture materials. Synthetic absorbable suture fibers, however, have been made from a new family of aliphatic polyesters developed in the early 1970s. If a suture is absorbable, its tensile strength loss must match the healing rate of the tissues to be closed, and the degradation products must be biocompatible and be metabolized by normal body metabolic mechanisms.

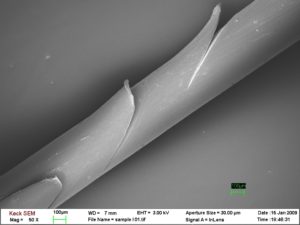

If there would be any meaningful textile structural design advancement in implantable suture fibers, it would be barbed suture fibers commercially launched by Quill in 2007. The most important advantage of barbed sutures is that there is no need to tie knots, and hence this knotless feature can simplify and speed up the wound closure and minimize the potential adverse untying of a knot that can lead to wound dehiscence. The barbs can be unidirectional or bidirectional. A unique biomedical application of barbed sutures is in cosmetic surgery.

The four most important properties of suture materials are physical and mechanical; handling; biological; and biodegradation. It is important to recognize that these properties are interrelated. For example, the capillarity of a suture material under physical/mechanical characteristics is closely related to the ability of the suture to transport bacteria, which is a biological characteristic. The modulus of elasticity under physical/mechanical characteristics is frequently used to relate to pliability of sutures under handling characteristics. The range of data shows the complexity and difficulty of the issues that implantable medical textile products have faced vs. traditional, non-implantable biomedical use.

There have been several technical advancements in the suture fiber arena in terms of fibrous materials and fiber structure. One example is genetically engineered spider silk fiber from Canadian firm Nexia Biotech. A spider gene is inserted in a goat and the recombinant spider silk is produced in goat milk and processed into silk fiber with the name Biosteel®.

The other example is the biodegradable pseudo-protein fiber made from amino acid-based synthetic poly(ester amide) (AA-PEA) pioneered in the Chu’s lab. The two most unique aspects of this new family of AA-PEA materials is its muted foreign-body inflammatory response and capability to promote wound healing. The third example is the unique sea/island cross-sectional morphology MonoFlex® suture fiber.

Cardiovascular devices

Vascular diseases frequently result in either the loss of lives or limbs, so the development of textile-based vascular grafts has been one of the most important biomedical advancements. This development has made significant progress, allowing the reconstruction of obstructed or injured blood vessels with remarkable success. The vascular graft market had a value of $2.48 billion in 2016, and is projected to reach $3.80 billion by 2022.

However, some serious problems, such as full-wall healing, remain unsolved. While homografts are still considered to be the preferred arterial replacement for small-diameter vessels (below the knee), they are used in limited quantity and are insufficient to meet the increasing needs for vascular replacement, due mainly to an inadequate supply, non-uniform properties, and difficulty in preparation.

The two most important fibrous polymers used for making vascular fabrics are poly(ethylene terephthalate) and expanded poly(tetrafluoroethylene). The former includes Dacron and has the largest market share. The latter is the same as Gore-Tex. In addition to these two common polymeric fibers as major sources for fabricating vascular grafts, the use of polyurethane-based elastomeric fibers like Spandex has been tried for improving the compliance of vascular grafts. The inherent porous nature of textile materials has provided the required space for the fibrous connective tissue to grow into for achieving full-wall healing.

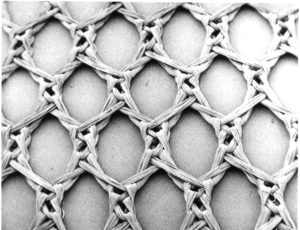

Currently, there are three basic textile structures—all different from each other in porosity, mechanical and biological properties—for vascular fabrics: woven, knitted and nonwoven. All woven and knitted vascular fabrics are made from poly(ethylene terephthalate), while the nonwoven vascular fabrics are made from expanded poly(tetrafluoroethylene), the same polymer for the non-absorbable Gore-Tex suture.

Woven structures provides strength with high dimensional stability and low permeability to blood, and it is less prone to kinking. It’s used mainly in large-diameter vessels like aorta and major arteries from which uncontrolled bleeding could lead to fatality. The main disadvantages of woven vascular fabrics are their very low healing porosity leading to poor healing, difficulty in suturing, fraying of cut edges, and poor compliance to the adjacent nature blood vessels.

In order to improve the healing porosity and compliance of woven vascular fabrics, velour woven vascular fabrics were introduced. These new fabrics were made by floating portions of the weft or/and warp yarns so that the numbers of intersections along both warp and weft directions were reduced considerably from the conventional 1 x 1 woven structure. Since the numbers of intersections of both weft and warp yarns are closely related to the mechanical and physical properties of the resulting fabrics, a significant reduction in these numbers would make the fabrics more flexible and porous. The floated portions of the yarns have another advantage: they produce three-dimensional loose surface structures as the framework for tissue attachment and ingrowth that conventional woven fabrics do not have.

Knitted vascular fabrics have a much higher porosity than woven grafts and hence show better full-wall healing. However, due to their high porosity, they are difficult to preclot during the time of implantation and therefore impose the problem of blood leakage. As a result, these are not normally used in large arteries where bleeding is a major problem. Knitted vascular fabrics are also softer and more flexible than woven grafts and show better compliance, and there are far more varieties of knitted than of woven structures. The current commercially available knitted vascular fabrics are mainly warp-knitted with a single- or double-velour surface structure.

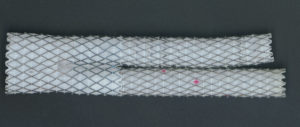

Beyond the traditional all textile-based vascular grafts, a relatively new vascular graft design became available as stent grafts that merge newer stent technology with traditional textiles. The main advantage of stent grafts, usually used to treat aneurysms, is the less invasive surgical procedures for delivery via a catheter.

The two most important criteria in designing vascular fabrics are porosity and non-thrombogenic surface. These are closely related because vascular fabrics require porous space for tissue ingrowth, which would ultimately lead to the formation of non-thrombogenic surfaces. The generation of a non-thrombogenic surface on synthetic vascular graft materials is one of the most important goals in the repair of damaged or diseased vascular systems. Incomplete healing imposes the continued risk of thrombotic occlusion, particularly in medium- and small-caliber blood vessels.

Because all of the existing commercial vascular grafts are constructed from a single type of non-absorbable fiber, poly(ethylene terephthalate) or poly(tetrafluoroethylene), their porosity is relatively constant and does not change with time. It is thus impossible to vary the porosity of these single-component fabrics so that they would be very tight during implantation (i.e., low bleeding porosity) to prevent the occurrence of blood leakage, and be very porous during healing (i.e., high healing porosity) to promote fibrous tissue ingrowth for a full-wall healing.

There are several approaches to try to design ideal vascular fabrics that would meet these two most important porosity criteria. Among them are the use of absorbable fibers as the sole component or as one of two components of a fabric and the theoretical prediction of the porosity of a fabric based on some mathematical formula are quite intriguing and appear to be promising for the design of the next generation of vascular fabrics.

The rationale of using absorbable fibers as components of vascular fabrics is threefold. First, since the absorbable component would eventually be biodegraded, the resulting vascular fabrics would have high healing porosity due to the new porous space generated from the disappearance of the absorbable components. This high healing porosity would induce the growth of an endothelial cell lining within the graft luminal surface. All the ingrowth mechanisms would require adequate porosity of the fabrics, and the use of absorbable fibers appears to be the most promising approach to achieve such a goal without compromising bleeding porosity during implantation.

Secondly, absorbable vascular grafts would not elicit permanent foreign-body reactions as non-absorbable fibers do and hence are more biocompatible and less prone to chronic inflammation, which can lead to delayed healing and a high risk of infection. Finally, absorbable vascular grafts could regenerate pseudo-arterial tissues with non-thrombogenic surfaces during the biodegradation process of the absorbable grafts.

Surgical mesh fabrics

Another common implantable medical textile product that has a long history of saving human lives is surgical mesh for body wall repair. Defects of the body’s tissues are the direct result of the radical resection of a cancer tumor, congenital lesions, infection and subsequent necrosis and debridement, violent crimes, accidents or large hernias.

One in every 200 U.S. adults has experienced a hernia problem. Attempts to close these large defects are essential to save the patient’s life, as well as to restore normal body functions. For those large defects lacking adequate tissue to permit primary repair, it is highly desirable to use materials of either a synthetic or a natural origin to reinforce tenuous aponeurotic closures and/or to bridge large defects in the abdominal or chest wall.

A wide variety of biological and synthetic textile materials have been used to repair a defective body wall. Synthetic textile materials for mesh use include metallic based (tantalum, stainless steel) and polymeric based (polyamide (nylon), polyester (Dacron), polytetrafluoroethylene (PTFE) or expanded polytetrafluoroethylene (Gore-Tex) and polypropylene (Marlex). The absorbable type includes PGA (chemically identical to Dexon suture), and polyglactin-910 (chemically identical to Vicryl suture).

More recently, new composite mesh products have been introduced for the purpose of reducing undesirable surrounding tissue adhesion and scar tissue onto mesh surface from foreign-body induced inflammatory response. For example, Genzyme introduced two unusual absorbable surgical meshes that are not based upon synthetic absorbable suture materials. These two composite surgical meshes, Seprafilm and Sepramesh, have both non-absorbable polypropylene fibers and carboxymethy cellulose and absorbable sodium hyaluronate component.

Synthetic surgical meshes are fabricated in either a woven or a knitted structure and exhibit various levels of porosity and strength with absorbable coating as a barrier for tissue adhesion or not. There are many innovative uses for surgical meshes in a variety of surgical areas, particularly for the protection of internal organs.

Research continues in biomedical textiles and fibers to improve the performance of these materials, which play a critical role in today’s practice of medicine.

C. C. Chu, Ph.D. is the Rebecca Q. Morgan ’60 endowed chair professor, Department of Fiber Science and Apparel Design and Biomedical Engineering Field, Cornell University, Ithaca, N.Y.

(http://chu.human.cornell.edu/)

Readers interested in an in-depth reading of this subject are invited to contact Janet Preus, senior editor, Advanced Textiles Source, to obtain a list of reference materials provided by Dr. Chu.

TEXTILES.ORG

TEXTILES.ORG