Polartec® introduces Polartec Power Fill™

June 20th, 2017

Polartec® has announced a new material designed as a passive insulation solution for the coldest conditions. Power Fill™ is a soft and pliable matrix of polyester fibers engineered with a proprietary hollow fiber construction forming thousands of air pockets that continuously capture and contain body heat and maintains an equalized thermal layer between the elements […]

Kingbird introduces STANDARD 100-certified threads and yarns

June 19th, 2017

Kingbird recently introduced yarns and threads that meet the STANDARD 100 by OEKO-TEX. This is part of the company's commitment to adhere to all global quality standards, including the Agreement on Textiles and Clothing, the Business Social Compliance Initiative and SGS quality tests. The STANDARD 100 by OEKO-TEX testing criteria involve assessing the quality of […]

New director named at Hohenstein’s Institute for Life Science

June 16th, 2017

Dr. Timo Hammer has been appointed to lead the William-Küster Institute for Hygiene, Environment and Medicine, otherwise known as the Institute for Life Science at Hohenstein's Research and Service Center. In a recent interview, Dr. Hammer, a textile scientist, outlined some of the services Hohenstein currently accomplishes. These include determining effectiveness of antimicrobial fabrics against various bacteria, […]

Plastic is recycled to make architectural mesh

June 12th, 2017

Kaynemaile™ architectural mesh, from “Lord of the Rings” set designer Kayne Horsham, draws on the designer's experience in the art of creating chainmail. During his work on the fantasy trilogy, he wove millions of rings into armor robes for Viggo Mortensen and Orlando Bloom. Horsham experimented with meshes using plastic via an injection molding process, […]

NC State opens new nonwovens facility

June 12th, 2017

North Carolina State University (NC State) recently celebrated the grand opening of a new nonwovens facility on campus. Nonwovens have long-standing and wide-reaching roots in North Carolina. About 40 percent of the U.S. nonwovens industry is based in the state, reports Behnam Pourdeyhimi, executive director of the Nonwovens Institute at NC State. The new manufacturing facility, […]

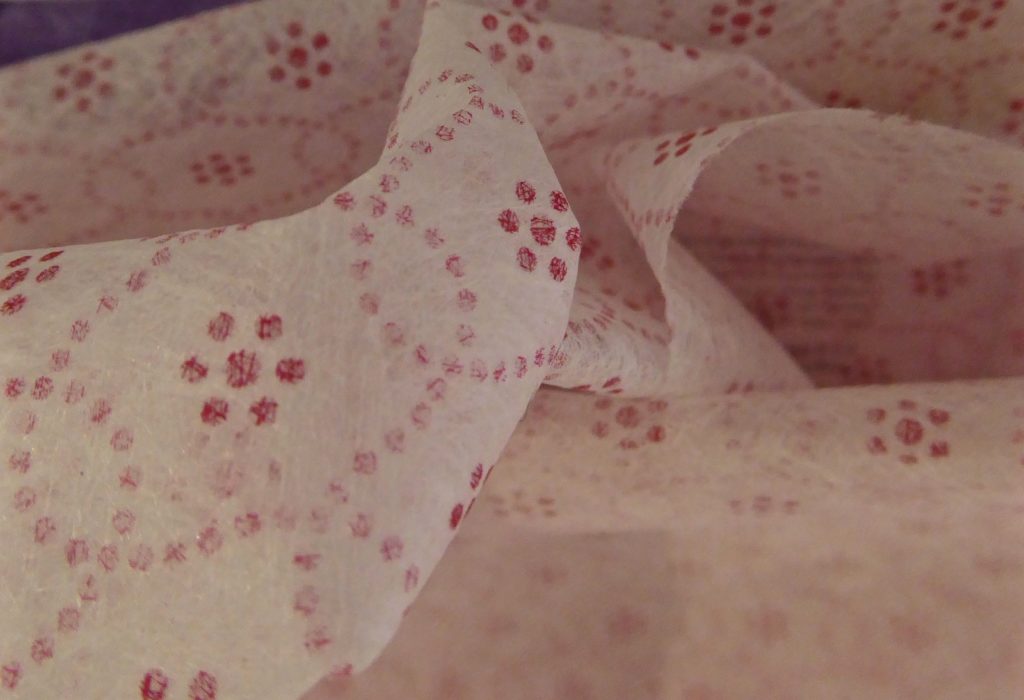

What can’t nonwovens do?

June 12th, 2017

When I started working as a writer and editor in the specialty fabrics industry, “nonwoven” meant an engineered textile that was used in a disposable end product: diapers and wet wipes – that sort of thing. Disposable nonwovens were (and are) a huge market. (How many parents use cloth diapers these days?) One of the […]

MISSION launches new cooling towel

June 12th, 2017

MISSION has recently unveiled a new temperature-control technology that the company says provides 30 percent greater cooling power than its original cooling towels. MISSION’s products are designed to help athletes combat the effects of heat and over-heating. "HydroActive Max" is made of a durable, soft-touch fabric that is machine washable and has built-in chemical-free technology. […]

The new nonwovens

June 12th, 2017

Improvements in performance include more eco-friendly materials and processes. The global market for nonwovens is expected to grow from its 2015 level of $2.9 billion to $8 billion by 2022, according to Stratistics Market Research Consulting, specialists in global cross-sector market research. Existing market sectors such as health, hygiene and automotive applications are expanding, and […]

Major retail brands adopt more sustainable practices

June 12th, 2017

Fashion forward means more fashion cycles and the days of three to four collections per year for a clothing design firm are gone. Sweden’s H&M, for example, introduces up to 16. That wealth of creativity and production has an impact on the environment, reports Fashionating World. The magazine cites an estimate from McKinsey that when […]

New SABIC filaments portfolio

June 8th, 2017

SABIC has unveiled a new portfolio of six high-performance filament grades for fused deposition modeling. The new filaments, designed for use with Stratasys Fortus printers, are based on the company’s Ultem polyetherimide (PEI) resin, Cycolac acrylonitrile-butadiene-styrene (ABS) resin and Lexan polycarbonate (PC) resin and offer the same composition as the company’s injection moulding grades. Manufacturers can use the filaments to produce a range […]

TEXTILES.ORG

TEXTILES.ORG