At the Parley Talk at COP21, Adidas and Parley for the Oceans demonstrated how the industry can rethink design and help stop the growing problem of ocean plastic waste. The result is an innovative footwear concept: a shoe 3D printed from waste plastic found in the ocean.

“World leaders forging an agreement is wonderful, but we shouldn’t need to be told to do the right thing,” said Eric Liedtke, Adidas executive board member responsible for global brands. “Together with the network of Parley for the Oceans, we have started taking action and creating new, sustainable materials and innovations for athletes. “The 3D-printed ocean plastic shoe midsole stands for how we can set new industry standards if we start questioning the reason of what we create. We want to bring everyone from the industry to the table and create sustainable solutions for big global problems.”

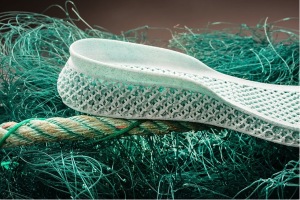

The concept shoe consists of an upper made with ocean plastic content and a 3D printed midsole made from recycled polyester and gill nets. The collaboration further extends the Adidas Futurecraft division that employs new manufacturing techniques, such as 3D printing, to create shoes.

“2015 is the year of the oceans: the ocean movement successfully brought the cause onto the COP21 agenda in Paris,” says Cry Cyrill Gutsch, founder of Parley for the Oceans. “Protecting life underwater became the 14th development goal of the United Nations. With a framework of political goodwill in place, it is the right moment to transform words into action. We are really excited to have Adidas supporting us in this journey and showing how you can take concrete steps in the right direction.”

TEXTILES.ORG

TEXTILES.ORG