An overview of wearables markets shows the variety of products available and in development.

Wearable technology is the term rocketing to the stars on Google Trends but it is almost entirely about wearable electronics today. This is a large ($14 billion) business for humans and nearly $1 billion for animals. It includes such items as electronic wristwatches, hearing aids, headphones and gaming headwear.

There are a variety of electronic collars for animals that light up, control behaviour and activate access. Wearable cameras for you and your pet are now very popular. The use of woven fabrics is minimal and low tech, involving perhaps a chinstrap, belt, woven collar or ear pad.

The total wearable technology market will leap to $71 billion in 2024, almost entirely due to new devices and fabrics.

Wearable phones

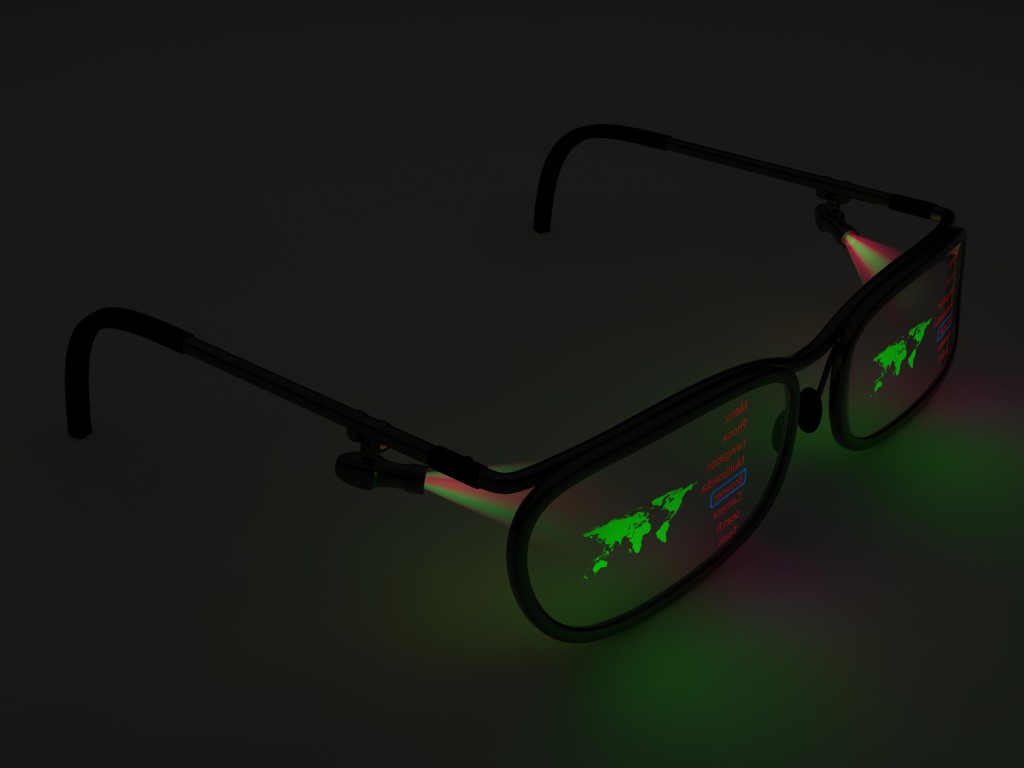

Primarily, the next twenty years of wearable technology will concern an immediate boom in things you put on, such as web-enabled watches and glasses monitoring sickness, fitness, dosage of sunshine, and offering games and other services. To begin, they are web-enabled phone peripherals, but increasingly they will be able to do the complete job of a phone—and affordably. This vast repertoire may make them difficult to use, except where completely new human interfaces are developed. (For example, there are smart glasses where you blink to take a picture.)

Brainwave monitoring

Brainwave monitoring headwear may seem a little creepy: a man in the U.S. is already steering his motorized skateboard by thought. What could be next? However, worn exoskeltons could give one “superhuman” powers even to a paraplegic. And there is an opportunity to make the unattractive outer scaffolding of today’s military and prosthetic exoskeletons into strong, electronic and electrical fabric that is not embarrassing or cumbersome.

Transition to apparel and patches

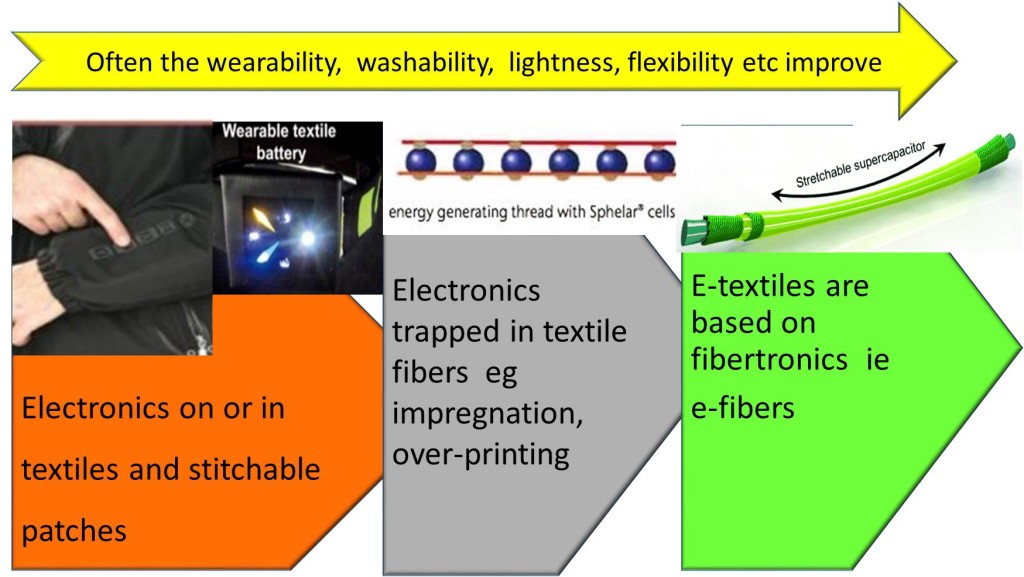

Overlapping that boom in wearable gadgets will be smart fabrics doing various “tricks,” but the jury is very much out on them. So-called e-fibers have already been made that conduct electricity or act as solar cells, batteries, supercapacitors also storing electricity, even transistors, sensors and moving color displays. However, will you wear the same clothes every day, or will this technology become so cheap that most of your clothing will, at minimum, generate electricity?

Industrial and medical uses are more plausible than everyday use at this stage. Think of it as a transition, as shown in Figure 1.

Fiber chemistry and structures

Familiar PET and other polymer fibers will be used, often in a smoother, more purified form. Already printed electronics and electrics on polymer film employ purified, planarised, biaxially-oriented PET and, a long way behind, PEN and polyimide. Some of this is stitched into clothing. We already have woven cotton labels containing Radio Frequency Identification (RFID) inlays on PET film stitched into sports shoes and other apparel, and there is considerable use of woven conductive fiber for anti-static clothing in semiconductor factories. There is even some use of glass fiber optics woven into textiles.

Powerweave textile makes and stores electricity

Imperial College London has been developing supercapacitor fabric for some years. It is formed into load-bearing structures and smart skin for vehicles. On the other hand, the European Commission Powerweave project brings together 13 European partners from seven countries. The project started in June 2012, will last 42 months and the total grant is a useful $5 million.

The Powerweave objectives include developing a knitted or woven fabric that will generate power from sunlight or ambient lighting and store the energy within itself. The aim is to generate 10W per square meter peak and to store 10Wh per square meter. They are developing photovoltaic PV fibers of diameter 150μm, generating 1.5mW/meter and rechargeable energy storage fibers also of diameter 150μm, storing 2mWh/meter, with a view to combining them later.

The participants seek to design and develop reliable interface and interconnection methods combined in a fabric structure of the photovoltaic and the energy storage fibers. They will connect the fabric and demonstrate operation in large area PV/storage applications.

Unusual solar cell on fiber

The chosen PV technology is Dye Sensitised Solar Cells (DSSC), which employ a photoelectrochemical effect, not a pn junction. Though relatively inefficient, they are flexible and much less sensitive to angle of incidence of radiation than silicon cells, and they perform over the widest range of light conditions. They are much less sensitive to shadowing than silicon and can be diode-free.

DSSCs utilise commonly available, low-cost processing equipment and materials, so they should be very affordable eventually. Partners in the project are EPFL in Switzerland where DSSC was invented, and Cyanine Technologies develops the necessary dyes, electrolytes and structures suited to fiber-format DSSCs.

Why supercapacitor fiber?

In this project, it is interesting that supercapacitors, not batteries, have been chosen as the power storage layers on the fiber, though the brief permits batteries to be considered. It is argued that they have high-power density, long lifetime and low internal resistance, and they can be constructed from commonly available, low-cost materials, so, like DSSC, they are potentially low cost.

Brunel University U.K. is developing chemical structures suited to fiber format supercapacitors. Multi-core melt spinning is being developed at CeNTI. Diverse fiber coating and deposition methods are being utilized at participants Centexbel and CeNTI.

With the diversity of technologies, the variety of entities involved in research and development, and the range of products and markets, it is not surprising that impressive growth is possible.

TEXTILES.ORG

TEXTILES.ORG