What’s realistic for smart textiles

The words “smart textiles” have generated much discussion in the industry and the media recently. India-based market research firm Markets and Markets has estimated the value of this high-tech textile sector to be about $4.7 billion by 2020. Given that the smart textile industry was estimated to be less than $1 billion in 2014, the anticipated growth is phenomenal: a cumulative annual growth rate of 30 percent.

In a speech April 1, when Dr. Rafael Reif, president of the Massachusetts Institute of Technology (MIT) announced the new public/private consortium, Advanced Functional Fabrics of America (AFFOA), he shared a prediction made by Dr. Yoel Fink, a member of the MIT faculty and the Director and CEO of AFFOA. Fink described the potential of AFFOA as the fiber equivalent of Moore’s Law. “You might call it the ‘AFFOA Law:’ the number of devices in a fiber will double every 12 months, inventing an industry that does not yet exist. Not just a handful of products, but a whole new industry,” Dr. Reif reported.

As the smart textiles sector is evolving and not yet really defined, to propose a bold projection to gauge the growth may be premature. Nevertheless, it sets the stage for this sector that has tremendous enthusiasm among stakeholders. This mood is quite evident with the government as well, as it has invested heavily in the AFFOA, whose overarching goal is to revolutionize textile manufacturing in the United States.

What does it mean to be “smart?”

Smart textiles are those that are nontraditional, have interactive functionalities and have new or non-commodity applications. This definition is broad-based to accommodate the diverse nature of the value-added textiles sector. It is not in the best interest of the industry to try to dwell too much on establishing a concise definition. However, as the field is nascent and emerging, it would serve the industry well to group those sectors that can be brought into the smart textiles folder.

It will be a challenge to adopt a universally acceptable definition to precisely categorize this sector, as it can involve the entire fiber-to-fashion supply chain in developing new advanced textile products. An inclusive description could be this: smart textiles are next generation advanced textiles for which applications are evolving and, in some cases, yet to be developed.

Smart textiles can have functionalities that allow them to actively sense, shape or protect. This categorization is broad based and can include almost all forms of textile structures that have improved functionalities and enhanced applications. The need of the hour is to convince the industry to agree with the basic understanding of the sector so that next steps to grow the sector can be undertaken in product and applications development, standardization—and tackling marketing and trade issues.

Characteristics and applications

Nontraditional textiles with improved functionalities need not specify raw materials or manufacturing processes, but can focus on characteristics, such as being active and reactive, and on their applications beyond the existing ones. Examples would include wrist bands and vests with electronic sensors for monitoring the body’s vital signs, geotextile products that can monitor and adjust to varying dynamic stress levels, and clothing that can measure ambient temperature and provide comfortable thermal effects.

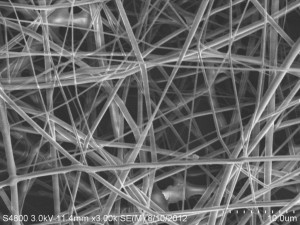

We can differentiate smart textiles from traditional industrial textiles in other ways. Here’s an illustration: nanofibers have value-added properties, such as having an increased surface area but still being lightweight—characteristics that are valuable in filtration applications. These are not smart textiles as they are not active, based on the definition given. If, however, these nanowebs are made catalytic to cleave toxic compounds using metal oxides, they become self-cleaning filters. These self-detoxifying nanofilters delineate how industrial textiles are different from actively functional smart textiles.

The tasks ahead

An important task confronting the industry is developing standards to govern the quality of smart textiles and to test these new and value-added applications, quantifying characteristics, evaluating safety requirements, and developing product labels for sales and marketing.

Additionally, as the smart textiles field is emerging, issues involving international trade must be addressed. It is important to work with the World Customs Organization and others concerning tariff codes. As the U.S. is the leader in the smart fabrics field, it can be an important player in export markets, so this aspect is important. In this scenario, trade associations such as the Industrial Fabrics Association International (IFAI) National Council of Textile Organizations (NCTO) and Association of Nonwoven Fabrics Industry (INDA) can work together as synergistic allies to create awareness of the sector and facilitate trade.

The U.S. and developed economies, such as the countries in the European Union, have advantages in developing and exporting textiles due to the quality of their products. Professional standardization bodies, such as the Switzerland-based International Organization for Standardization (ISO) and other national bodies, such as the American Society for Testing and Materials (ASTM), American Association of Textile Chemists and Colorists (AATCC) and the Technical Association of Pulp and Paper Industry (TAPPI) have developed many standards related to textiles, pulp and paper products. In the case of nonwovens, the U.S. headquartered Association of the Nonwoven Fabrics Industry (INDA) and Belgium-based European Disposables and Nonwovens Association (EDANA) have developed standards for nonwovens. Such an effort is also needed for the smart textiles sector.

A creative approach

As smart textiles are generally multicomponent products with one or more non-textile components such as electronics, organic and inorganic products, or biomimetic materials, it will be useful to develop standards for the applications of the final smart textile products. For example, a wearable textile with medical and sport applications should need standards to quantify its end-use applications such as monitoring the body’s vital signs.

Although durability of the product to mechanical and multiple stresses is important, it will not be logical to use the existing standards to test laundering and mechanical durability of the smart textiles that have electronics incorporated in them. The industry has to find creative ways to develop new standards. In the case of wearable electronic textiles, one has to first evolve standards for testing the new and intended application, which in this case could be as a sensor for blood pressure, heart rate and other vital signs. Existing testing standards for wash durability and mechanical strength can be used to test the textile component and can be used as supplementary quality information.

International trade bodies in the field, such as IFAI, can work with professional standardization bodies such as ASTM International and AATCC to develop application-specific standards for smart textiles. AATCC has recently created a technical committee on wearable electronics to look into standardization requirements for electronic textiles.

Sustainability and safety

An important aspect that has not garnered quite as much attention is the safety attributes of multicomponent smart textiles when used on humans. In the case of wearable electronic textiles that have chips and electronic circuits, safety issues have to be taken into account. Another aspect to consider is the sustainability of these products; the smart textiles sector has to be proactive in this issue and efforts have to be made to make these new materials and end products environmentally and economically sustainable. This means that safety standards and sustainability benchmarks need to be addressed.

What’s next?

As IFAI is an organization that serves members who manufacture and market industrial textiles, it can take a leading role in categorizing and standardizing products. IFAI can coordinate with national and international bodies to evolve meaningful test methods and trade codes. There needs to be good outreach with nontraditional textile schools in the U.S., such as those dealing with material science disciplines, as the smart textiles field is truly multidisciplinary. Outreach and engagement with all stakeholders, including the departments of commerce of concerned governments, are needed to grow the field and market smart textiles and applications in the future.

Seshadri Ramkumar, Ph.D., FTA (Honorary) is a professor in the Nonwovens & Advanced Materials Laboratory, Texas Tech University.

TEXTILES.ORG

TEXTILES.ORG