With the growing emphasis on multiple functionality and comfort in safety apparel, breathable durable water repellency (DWR) has become an important attribute of most safety clothing and workwear.

Uniforms and workwear coated with PVC (polyvinyl chloride) or its greener alternative, polyurethane, successfully repel water, oil, dirt, chemicals, blood and airborne pathogens; but they are hot, heavy and do not breathe to allow perspiration to pass through to the outside. This can create further hazards, such as heatstroke or exhaustion.

Since the development of DWR (durable water repellent) textile finishes based on PFCs (perfluorochemicals) in the 1950s, the lives of first responders, military personnel, and outdoor industrial workers have been made safer and more comfortable.

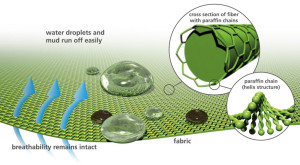

Applied to the face of outerwear fabrics, DWR finishes prevent the fabric from “wetting out” without inhibiting breathability, making them especially critical for the functionality of the waterproof breathable laminates used as barrier fabrics in much of today’s safety apparel and footwear.

“DWR plays an important role across the end use applications of our technical fabrics,” confirmed Amy Calhoun, enterprise communications at W.L. Gore & Associate, which supplies the makers of military and safety equipment through its protective fabrics division. “For example, in fire turnout gear and military apparel, DWR can dramatically reduce the extra weight burden that occurs when fabrics are wet. This not only impacts the comfort of the individual, but their performance as well.”

The most effective DWRs are those based on PFCs using eight carbon atoms, referred to as C8 or long-chain chemistry. However, these PFCs contain perfluorooctane sulphonate (PFOS) and perfluorooctanoic acid (PFOA), substances which have been found to be toxic, persistent and bio-accumulative.

In the US, the Environmental Protection Agency (EPA) legislated the virtual elimination of PFOA in products by the end of 2015. In addition, the EPA has proposed a ban on the manufacture and import of long chain PFCs and treated articles from 2016 on. PFOS has been banned in Europe for several years, and there are proposals by the REACH organization and the EU Council of Ministers to ban the use of PFOA and fluoropolymers in all industries.

Most of the outdoor industry is transitioning into short-chain or C6 compounds, which do not contain PFOS or PFOA, and break down more readily in the environment. Many are also pursuing the development of PFC-free alternatives in conjunction with the chemical and technology suppliers.

The textile and technology suppliers for safety apparel and workwear are also making the transition into C6 fluorine compounds. For example, Helly Hansen Workwear eliminated all C8 treatments from their production in 2014; and Gore Fabrics eliminated all PFOA from its supply chain for its ePTFE-based GORE-TEX® laminates in 2013.

While there have been some complaints that C6 technologies are less durable than their C8 counterparts, or require a higher rate of application, most textile companies confirm that comparable efficacy can be achieved via a learning curve.

At Gore, the transition to C6 DWRs “was accomplished without a need to increase the amount of chemicals used in the application process or compromising the repellency performance end-users expect,” said a company press release.

Lisa Hardy, North American marketing manager for Teflon™ textile finishes at Chemours™, commented on the company’s Teflon™ Shield C6 fabric protector. “It’s not a drop-in replacement. It may take some recipe adjustments or cleaner fabrics, or as a last resort, more product.”

According to Chad Kelly, global product and brand manager for eVent® fabrics, the ePTFE membrane manufacturer is “fully transitioning into C6-based DWR treatments.”

“As we grow our business in the workwear market and introduce new technologies, we will also meet the demands of that market, which, I expect, with time, will also find that moving to C6 treatments will not compromise performance in workwear,” he added.

However, questions remain regarding the safety of C6 compounds, as they also contain PFCs which can accumulate in the environment. With NGOs such as Greenpeace pushing to eliminate fluorine-based DWRs entirely, technology companies are digging deeper into the development of PFC-free alternatives.

These are based on various technologies, ranging from paraffin or silicone applications, to nano-technology, plasma treatments and biomimetic, multi-branched dendrimer structures.

The key to the performance of all DWR finishes is that they lower the surface tension, or adhesion, of the fabric, changing the angle of contact between a drop of liquid and the textile surface. The greater the differential between the molecular energy of liquid and the surface, the more the fabric repels the liquid. Liquids such as water have a higher molecular energy and are easier to repel than oil or chemicals.

The bottom line is that non-fluorine DWR formulations do not lower the molecular energy of the textile surface as efficiently as those based on perfluorinated compounds. While non-PFC treatments may offer “adequate” resistance to rain for the outdoor industry, their performance thus far has been sub-par when it comes to protection against oil, dirt, chemicals, blood, and other substances that might impede the efficacy of a textile laminate in safety clothing.

Schoeller Technologies’ non-PFC ecorepel® DWR finish has been well-accepted in the outdoor industry. However, Schoeller is not currently promoting its use in safety apparel and workwear.

“At this time, and for the workwear market, PFC-free finishes are not often in demand. One of the requirements for workwear is the ability to repel oil-based substances and so far it is not possible to achieve this without PFCs. Short chain DWR finishes are state of the art today,” said Dagmar Signer, marketing communications for Schoeller.

Fluorine-free HeiQ BARRIER ECO has just introduced improved versions of its technology at the recent ITMA exhibition. However, HeiQ CEO Carlo Centonze advised, “Generally using fluorine-free technologies in workwear is more difficult. Industries that are looking at soil release and easy clean rather than direct repellency can use fluorine-free DWRs. Still requiring fluorine are oil industry, fire fighters, and [applications for the] army.”

At SympaTex®, which has worked closely with Rudolf Chemie to develop non-fluorine BIONIC FINISH ECO® finish for their membrane fabrics, the verdict is similar, according to business development manager Heather Santos. “Typically we do not use BIONIC FINISH ECO® for contract and workwear because the customer still wants oil repellency. We suggest the BIONIC FINISH ECO® if water repellency only is needed.”

Chemours’ Lisa Hardy concurred “The biggest difference today provided by short-chain chemistry, such as our Teflon™ fabric protector, vs. our non-fluorinated Teflon EcoElite™ renewably sourced finish, is that short-chain product repels oil, and non-fluorinated does not. In workwear and likely safety wear, oil repellency is a key functionality needed and we think those applications will stick with short-chain products to maintain the benefit.”

The quest for DWR applications that are sustainable as well as high-performing has become a holy grail. W.L. Gore & Associates recently announced that it will invest over $15 million over the next five years to explore alternative DWR solutions with an improved environmental profile and comparable or better comfort and performance.

The safety apparel industry must work alongside its suppliers to insure the timely development of appropriate DWR finishes for its customers. For first responders, military personnel, and outdoor industrial workers, sustainability in apparel is desirable; but safety and performance are non-negotiable.

Debra Cobb is a freelance writer with extensive experience in the textiles industry.

TEXTILES.ORG

TEXTILES.ORG