Quantifying the benefits of compression apparel on athletic performance.

Ever since 1995, when Kevin Plank launched Under Armour based on a pair of compression shorts from his University of Maryland football uniform, compression apparel has been a hot topic in athletic performance wear. The popularity of these snug-fitting, elastomeric garments has created a global market valued at $2.38 billion in 2014, according to a recent study by Persistence Market Research. The study also predicts that the industry will continue to grow, reaching a value of $3.23 billion by 2020.

The marketing of compression apparel to athletes is based on the idea that it improves performance by reducing lactic acid levels and heart rate, increasing oxygen efficiency and wicking away moisture to lower body temperature. Compression brands also claim that the products aid in post-activity recovery by stabilizing muscles and joints to prevent tears and fatigue. Yet laboratory tests over the years have been unsuccessful in quantifying the physiological benefits of compression apparel for athletic performance, according to a recent article in The New York Times Well blog.

The article cited a study of compression leg sleeves at the Institute for Exercise and Environmental Medicine at the University of Texas Southwestern Medical Center in Dallas, published this past January in The International Journal of Sports Physiology and Performance. The study confirmed that there was “no statistically significant difference” in the performance of sixteen competitive distance runners when wearing the compression garments, versus wearing non-compressive athletic clothing.

The standards question

While medical-grade compression therapy, as prescribed by physicians, has a strict set of standards and regulations, there are no industry-wide standards for testing and quantifying the physiological benefits of compression apparel for athletes. Testing the effects of compression apparel on performance generally consists of measuring the heart rate, respiration, biomechanics, and lactate levels of a group of athletes—usually runners on a treadmill—at various intervals during a period of exercise.

Ze’ev Feig, CEO of the compression apparel company Zensah, believes that such laboratory studies are inherently flawed. “These studies use competitive runners—a specific pool already very well trained, and already performing at their maximum,” Feig says.

“A study of ten to sixteen people is inadequate. There is not enough data, or a wide enough pool, to say that there is no physiological effect,” he adds. “Performance is very individual; you can’t put a number on it. If our garments didn’t work, my competition and I would be out of business.”

Zensah’s seamless leg sleeves, said to be the top-selling leg sleeve in the US, are worn by athletes from basketball pros to runners to ballerinas. The sleeves are thoughtfully designed, featuring chevron ribbing with variable zones of compression. Can millions of customers be wrong? Or is the controversy a question of bad science versus marketing hype?

Medical testing

The Hohenstein Institute, which developed the HOSY system for testing medical compression textiles, offers a quality label for non-medical compression textiles as well; but the label simply confirms the compression level as measured against the manufacturer’s data.

“However, there is a significant difference in how the results are assessed,” explains director of the Hohenstein Institute Florian Girmond on the company’s website. “With medical products, there are clearly defined requirements, but for non-medical textiles so far there are not. At least in theory, this can lead to critical situations for the manufacturer.”

Just released in September, the institute’s most recent study, Compression Technology—Quantifying the Physiological Benefits, points out that many compression tests are conducted as feasibility studies, limited to testing one type of textile from a single company, without taking into account the influence of textile construction.

Dr. Jan Beringer, head of R&D for the Function & Care department at the Hohenstein Institute, believes that in order to understand the benefits, every compression garment should be tested and custom fit to the individual dimensions of the wearer.

“Effective, comfortable compression requires precise design and manufacturing,” says Beringer. “Testing is the only way to be certain that a garment’s compression profile and thermophysiological properties are correct.”

The study focused on the benefits of compression garments with relation to endurance performance, examining the impact of factors such as the level of compression, the compression gradient, the textile construction, and the heat and moisture management of the fabric as relating to thermo-regulation. Thirty different garments at different stretch levels, different fiber mixtures, and varied knit construction were tested. The ten subjects—all experienced runners—were monitored for heart rate, oxygen demand, blood lactate and body temperature. The study did not include testing of compression’s effect on recovery.

While there was inconclusive evidence of the physiological benefits of compression textiles overall on running speed and endurance in the Hohenstein study, the tested compression textiles did not lead to heat stress, and fabrics with higher stretch levels exhibited better moisture management.

Most of the participants preferred wearing the compression garments versus non-compression garments for their workouts, prompting a conclusion that wearing compression textiles “can lead to a positive psychological effect, increasing motivation and therefore running performance.”

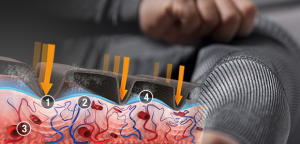

Testing by the Swiss research and development company X-Technology, makers of the X-BIONIC® brand of compression clothing, also indicated that textile formation is critical to performance in compression apparel. The company’s Partialkompression® is a unique textile construction that applies targeted pressure on 1 millimeter-wide ridges. The compression-free areas are said to allow blood to circulate unimpeded, promoting cooling and enhancing the athlete’s performance.

Hannes Asam, X-Technology’s communication director, explains, “In extreme situations endurance athletes use up to 97 percent of their energy only for temperature regulation. You can imagine what a difference even the smallest support (or limitation) of thermoregulation can have on marathon distances or ultra runs.

This is exactly where our Partialkompression® has its big advantage. It combines compression without neglecting the cooling process of the body (pushing blood in the capillary system below the skin, to improve heat exchange).”

Tests by the Centre for Mountain Sports Research and Health (CeRiSM) at the University of Verona confirmed that athletes wearing Partialkompression® garments showed better endurance, lower heart rates, and less heat generation than when wearing either non-compression or full-surface compression garments.

With an increasing variety of non-medical compression textiles and garments hitting the market, it appears unlikely that an industry standard for physiological performance benefits will be developed any time soon. Based on empirical evidence, consumers feel better and are motivated to perform better when wearing compression garments for athletics. However, textile construction may have a significant effect on the results.

Debra Cobb is a freelance writer with extensive experience in the textile industry. She is based in North Carolina.

TEXTILES.ORG

TEXTILES.ORG