From spider silk to bio-fabrics, the future of fiber has endless possibilities, according to Trenton Horinek, business development manager, Hologenix LLC.

In a presentation, “Fibers of the Future,” at IFAI Advanced Textiles Expo, Horinek first offered a look back at the history of manmade smart fibers, focusing on what he deemed the forefathers: GORE-TEX®, a waterproof, breathable fabric membrane; LYCRA®, an elastane fiber with unique stretch and recovery properties; COOLMAX®, a moisture-wicking fiber; and antimicrobial fibers. Each breakthrough offered a new direction to take fibers and fabrics as they were gradually made with smarter properties to become more interactive.

Focus on infrared

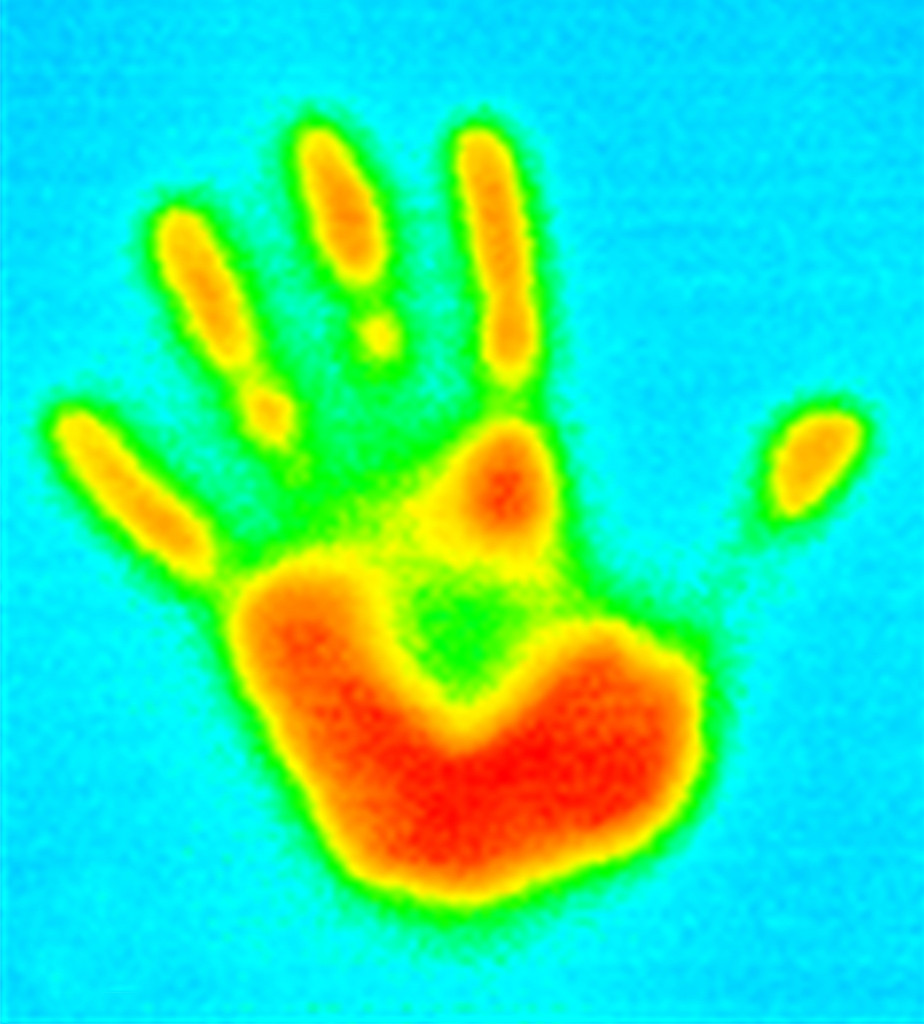

These laid the foundation of more recent technologies such as infrared and ceramic yarns. Since the human body emits infrared waves (heat), more companies are looking to create fibers that interact with the body’s own heat to provide benefits back to the wearer of the fabric. Applications for infrared yarn include veterinary products, wetsuits, bedding, outdoor apparel and military apparel.

Horinek provided three examples of infrared fibers: energear™ from Schoeller Textil AG, a fabric made with a specially formulated mineral combination that reflects the body’s far infrared rays (FIRs) back to the wearer, promoting blood circulation and increasing oxygen levels in the blood; Emana®, a smart yarn from Solvay S.A. embedded with bioactive minerals that absorb the body’s heat to provide thermo-regulation properties and improve blood micro-circulation; and Celliant®, Hologenix’s bi-component fiber made with a special mix of thermo-reactive minerals that recycles and converts radiant body heat into infrared energy. The active minerals in Celliant are ground into particles that are less than a single micron. Millions of these minerals are extruded into a resin that is loaded directly into the core of the fiber, ensuring the technology lasts the lifetime of the material, without washing out or breaking down.

Additional technologies

In addition to continued research into FIR technology, Horinek says that carbon fiber-based yarns should be used more. SIGRAFIL® C from SGL Group, for example, is a thermoplastic-compatible fiber with industrial applications spanning adhesives to aerospace and automotive industries. Textro-Yarns® from Textronics Inc. will also be used more in the future, thanks to their stretchiness and electrical conductivity.

Horinek called graphene one of this century’s greatest inventions. The possibilities really do seem endless for the extremely thin, almost transparent layer of carbon atoms bonded together in a hexagonal pattern. Applications from bendable cell phones to medical products are possible.

Synthetic spider silk will also play a major role. Modeled after the silk spiders use to create their webs, Spiber Inc. is developing a process to produce a tough, lightweight silk that could be useful for not only printing onto garments, but also for the automotive and medical industries.

Finally, Horinek introduced what is, at this point, still largely a concept: bio-fabrics. An example given of what these plant-based fibers could do involved a rug, where a type of circuit could be built into the rug that would allow it to change color based on heat levels.

TEXTILES.ORG

TEXTILES.ORG